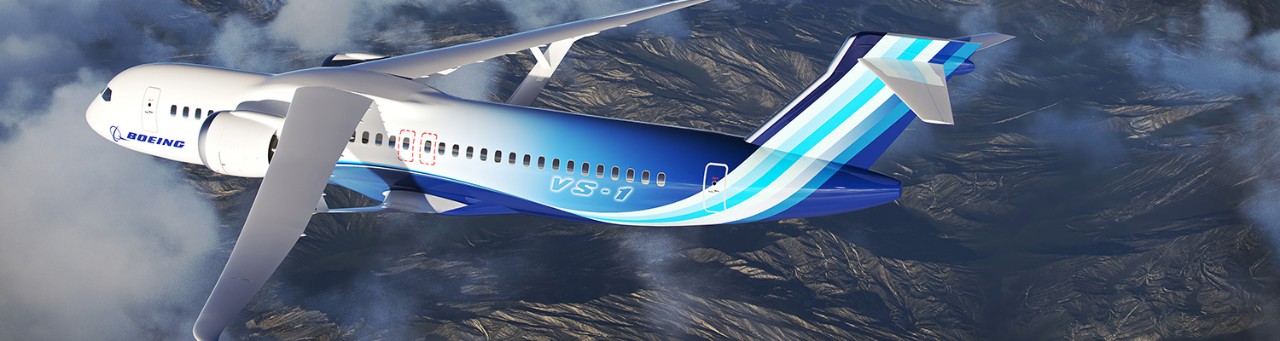

There’s more innovation underway today at Boeing than at any time in our storied history.

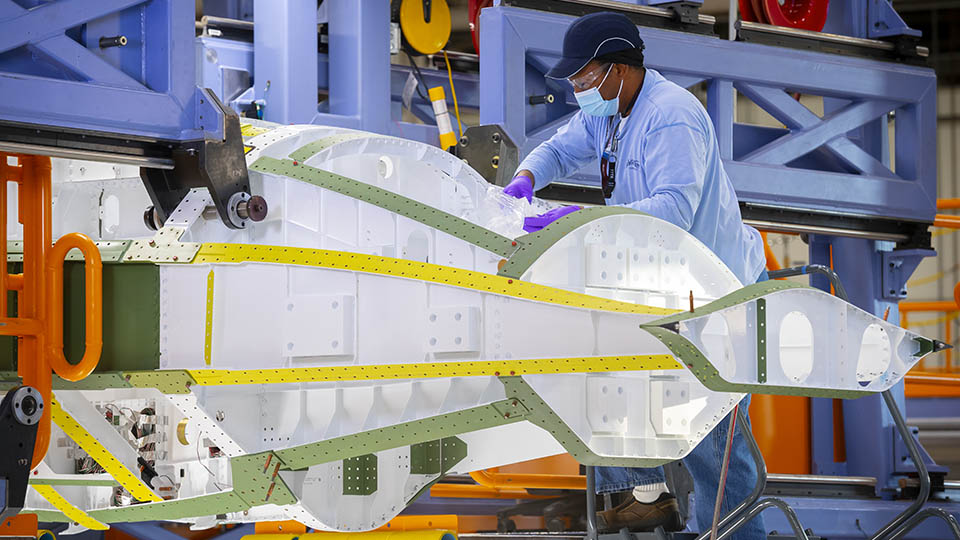

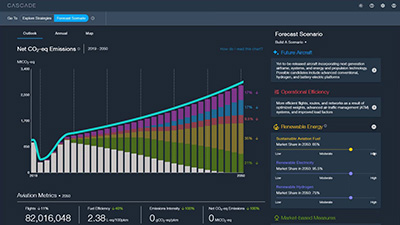

Teams across the global Boeing network are transforming how we design and build our products, the systems that enable us to work more efficiently, and the work we do to improve the environmental performance of our products and internal operations.

With more than $3 billion invested annually in research and development, Boeing drives innovation that will transform aerospace and defense as we know it. Making it all possible is the ingenuity and passion Boeing employees and global partners demonstrate when developing innovations that help blaze new trails.