Global defense agencies are seeing their traditional technological advantages threatened by peer and near-peer adversaries. To win the future fight, they not only need cutting-edge capabilities – they need the entire development, procurement and operational lifecycle to be faster, more agile and more insightful than ever before while exceeding the most demanding levels of quality.

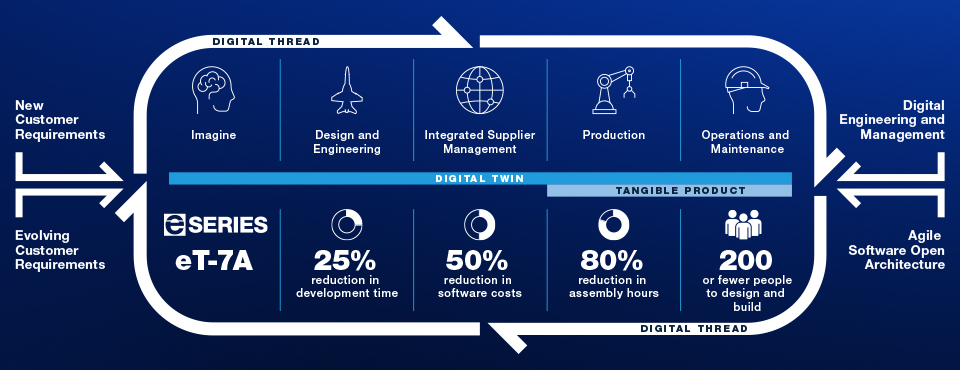

Boeing continues advancing – and deploying – the technology, tools and talent necessary to create a truly digital value stream from requirements definition to retirement; a production system that’s digital, scalable, modular and platform-independent; and open systems software development that enables the rapid insertion of capabilities and improvements to new and existing products.

Boeing’s first century was largely defined by its innovative aerospace products – “what we built”. Our second century is all about innovating “how we build” and delivering the capabilities customers need to meet their strategic and tactical mission objectives.