At a glance

Boeing is fully confident in the safety and longevity of the 777. With three decades of innovation in design and production and more than 3.9 billion passengers safely flown, the 777 family is the most successful widebody family in aviation history.

As of December 2023, the 777 family has safely transported more than 3.9 billion passengers on 15.9 million revenue flights

120,000 cycles of simulated in-service conditions during rigorous fatigue testing, 3 times the design service objective

The highest-cycle 777 in service has accumulated about 43,000 flight cycles since its delivery in 1997

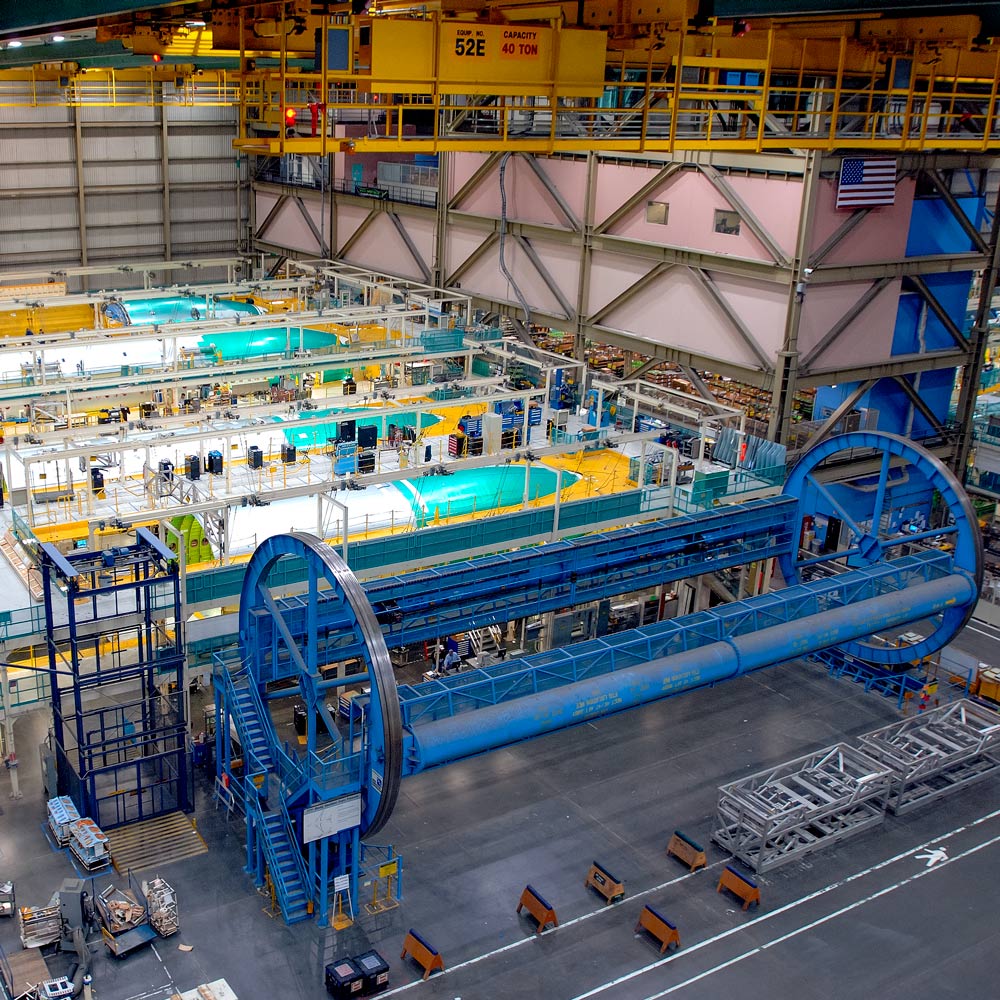

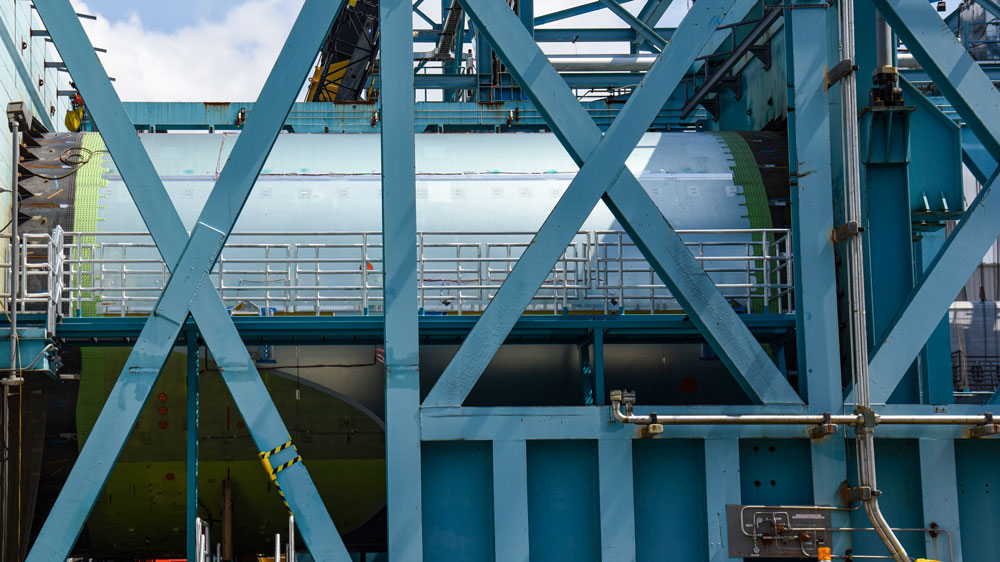

Fuselage assembly

Boeing builds all models of the 777 family at its Everett, Washington, factory. As with any program, the company has made continued improvements in the production system over nearly 30 years to improve workplace safety, quality and production operations, all with careful assessment, rigorous review and FAA oversight.

One example is determinant assembly. A long-standing manufacturing methodology not unique to any industry, determinant assembly involves designing parts with certain features so that they precisely align to each other, instead of being aligned to tooling. (This is also known in industry as part indexing.) For example, two fuselage panels to be joined could each be fabricated with a pilot hole that would align the panels to each other. Boeing first tested the methodology in 777 fuselage production in late 2005, 10 years after the first 777 entered service.

Early in production, Boeing assembled 777 fuselage sections using, fixed, floor-mounted jigs.

Early in production, Boeing assembled 777 fuselage sections using, fixed, floor-mounted jigs.

The partially built assemblies were then craned into a massive turn tool to rotate them upright, then craned back to complete assembly. This method was replaced by determinant and upright assembly, which improved workplace safety and quality.

The partially built assemblies were then craned into a massive turn tool to rotate them upright, then craned back to complete assembly. This method was replaced by determinant and upright assembly, which improved workplace safety and quality.

Boeing first tested upright, determinant assembly in 777 production in late 2005.

Boeing first tested upright, determinant assembly in 777 production in late 2005.

Boeing began planning to incorporate determinant assembly for 777 fuselages in 2013, as part of an initiative to improve workplace safety and quality in fuselage assembly. Known as fuselage automated upright assembly (FAUB), the effort also incorporated automated, guided robots to drill and install approximately 50,000 fasteners that had traditionally been done by hand. Boeing incorporated the changes in a portion of the Everett factory in 2015, fully implementing it in production by year end, under FAA oversight.

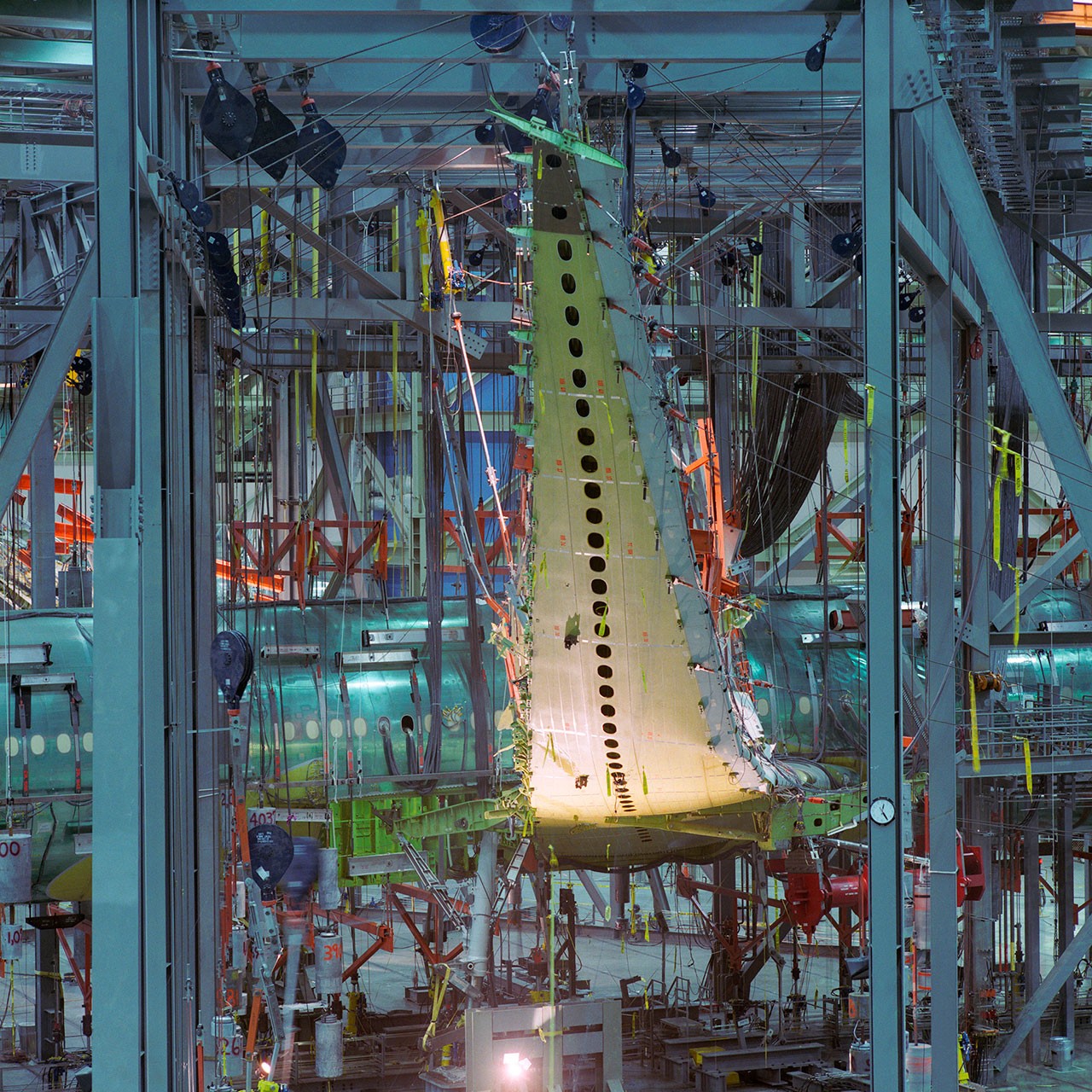

After careful evaluation, in mid-2019 Boeing began changing the type of automation in the assembly of the forward and aft fuselage sections from robots to flex tracks. First developed by Boeing Commercial Airplanes, flex tracks are an automated drilling technology proven effective on commercial programs such as the 787 Dreamliner and defense programs as well as in the later stages of assembly of the 777. Mechanics attach flexible tracks spanning the fuselage skin, then numerically controlled drills ride along the tracks to drill holes while the mechanics manually attach fasteners on the inside. The decision to change approaches, under FAA oversight, was driven by experience that showed flex tracks deliver higher quality, requiring less work by hand and with higher reliability, than what the robots had been capable of in the forward and aft fuselage areas.

Before the decision was made to implement flex tracks, the 777 program redesigned portions of the build process with rivets and less difficult forms of fasteners. Taken together, those changes and the flex track solution improved both safety and quality over the robot technology in forward and aft as well as the pre-2015 production process.

While this change sometimes is referred to as the discontinuation of FAUB, it’s notable that 777 fuselage sections are still built using automation and determinant assembly, though it is through modified means. Boeing also continues to use autonomous robotic technology to assemble the mid-fuselage section of the 777 and in other portions of production, including at the Composite Wing Center, where certain 777X wing components are fabricated, and on the Horizontal Build Line, where 777X wings are assembled.

All of these applications were implemented following the same careful assessment, rigorous review and FAA oversight, and all are performing to specification, producing assemblies that achieve quality expectations and conform to design requirements.

Designed to improve workplace safety and quality, Boeing’s FAUB initiative included determinant assembly as well as autonomous, guided robots that drilled and installed fasteners to form 777 fuselages.

Designed to improve workplace safety and quality, Boeing’s FAUB initiative included determinant assembly as well as autonomous, guided robots that drilled and installed fasteners to form 777 fuselages.

A flex track joining fuselage sections in 777 final assembly in May 2012. Boeing incorporated flex tracks into the assembly process for forward and aft fuselage sections in mid-2019.

A flex track joining fuselage sections in 777 final assembly in May 2012. Boeing incorporated flex tracks into the assembly process for forward and aft fuselage sections in mid-2019.

Structural testing

Boeing subjected the 777 to a comprehensive testing program to demonstrate the safety, performance and reliability of the design. During static testing of the 777 in 1995, Boeing validated the structure could withstand “ultimate” load, 150% of the highest loads any airplane would encounter in service.

In 1995, Boeing also began fatigue testing to verify the durability of the airplane structure. One hundred computer-controlled hydraulic actuators simultaneously applied loads to the airframe to simulate all conditions experienced during typical in-service operations, including pre- and post-flight taxi, pilot maneuvers, wind gusts and cabin pressurization. At its completion in 1997, the 777 fatigue test was the most comprehensive Boeing had performed to date – 120,000 cycles, or three design lifetimes – demonstrating excellent durability.

During static testing of the 777 in 1995, Boeing validated the structure could withstand “ultimate” load, 150% of the highest loads any airplane would encounter in service.

During static testing of the 777 in 1995, Boeing validated the structure could withstand “ultimate” load, 150% of the highest loads any airplane would encounter in service.

As part of the FAUB initiative, Boeing began extensive testing of determinant assembly in 2013. This included assembling an aft fuselage more than a dozen times using the methodology, ultimately performing fatigue testing on the fuselage to three times the design service life (120,000 cycles) – the same amount as for the certification of the first 777 airplane. There were no findings related to the determinant assembly process.

Beginning in 2013, Boeing undertook extensive testing of FAUB, which included assembling a 777-300ER aft fuselage more than a dozen times using the determinant assembly process.

Beginning in 2013, Boeing undertook extensive testing of FAUB, which included assembling a 777-300ER aft fuselage more than a dozen times using the determinant assembly process.

In 2013, Boeing performed fatigue testing on an aft fuselage produced by FAUB to 120,000 cycles, three times the design service life, with no findings related to the determinant assembly process.

In 2013, Boeing performed fatigue testing on an aft fuselage produced by FAUB to 120,000 cycles, three times the design service life, with no findings related to the determinant assembly process.

The change to the determinant process was supported through appropriate engineering evaluations, updates to engineering drawings and oversight, and remains in place today. Either type of process – floor mounted or determinant – can have fit-up (shimming and pull-up) occurrences, and Boeing manages them appropriately to ensure product integrity regardless of manufacturing method. After nearly a decade of using determinant assembly for 777 fuselages, there have been only small, local adjustments for fit-up forces with the process, with no change to the design life or durability of the airplanes.

Ongoing fatigue testing of Boeing's newest widebody airplane, the 777-9 (777X), recently reached 40,000 cycles, approximately 1.2 design lifetimes.

Ongoing fatigue testing of Boeing's newest widebody airplane, the 777-9 (777X), recently reached 40,000 cycles, approximately 1.2 design lifetimes.

Fostering transparency and openness

Safety and quality are core values at Boeing. We design and build all our airplanes to meet rigorous engineering specifications and FAA requirements, ensuring compliance with safety standards. We continuously propose improvements, supported by extensive data and testing, with oversight from the FAA for approval. Our culture fosters transparency, accountability and open communication, empowering employees to speak up through our confidential reporting channel, Speak Up. Reported concerns are thoroughly reviewed, and we take action while strictly prohibiting retaliation. We are committed to maintaining the highest levels of safety and quality through open dialogue and continuous improvement.

Frequently Asked Questions

FAUB was an initiative to enhance workplace safety, quality and efficiency in 777 fuselage assembly through improvements to assembly methodology, tooling and technology. Best known for its incorporation of automated, guided robots to drill and fill fasteners, the effort also included determinant assembly, which Boeing first tested in 2005, as well as process improvements. All were subjected to careful assessment, rigorous review and FAA oversight prior to implementation in late 2015.

Determinant assembly is a long-standing manufacturing methodology where parts are designed with certain features to precisely align them to each other, rather than to tooling, during assembly. For example, two fuselage panels to be joined could each be fabricated with a pilot hole used to align them to each other. This method is not unique to any one program, company or industry.

Yes. This method is not unique to any one program, company or industry.

Boeing carefully monitors the production system under established regulatory protocols and processes to assess issues as they arise, regardless of build methodology. The introduction of determinant assembly into 777 production followed careful planning, extensive engineering evaluations and updated engineering tolerances validated by testing, all under FAA oversight. After nearly a decade, only small, local adjustments for fit-up forces have been needed, with no change to design life or durability.

Boeing first evaluated determinant assembly for 777 fuselage assembly in late 2005, ahead of extensive evaluations beginning in 2013 with the FAUB initiative. During this testing, Boeing assembled an aft fuselage more than a dozen times using the methodology and tooling, ultimately fatigue testing an aft fuselage for 120,000 cycles with no related findings.

Boeing implemented determinant assembly, replacing fixed tooling, to improve workplace safety and ergonomics.

With three decades of innovation in design and production, the 777 fleet has safely flown more than 3.9 billion passengers around the world. We are fully confident in the safety of the 777, which remains the most successful widebody airplane family in aviation history.