There’s more innovation underway today at Boeing than at any time in our storied history.

Inside innovation at Boeing

Our people

Engineering excellence is the foundation of what we do. For more than 100 years, Boeing engineers have led aerospace innovation. They tackle the toughest technical challenges and deliver safe, practical solutions that improve mobility, sustainability and the everyday lives of people around the world. Leading this community of experts are members of the Boeing Technical Fellowship, who lead Boeing’s technical vision and guide the future of the aerospace industry.

Technologies

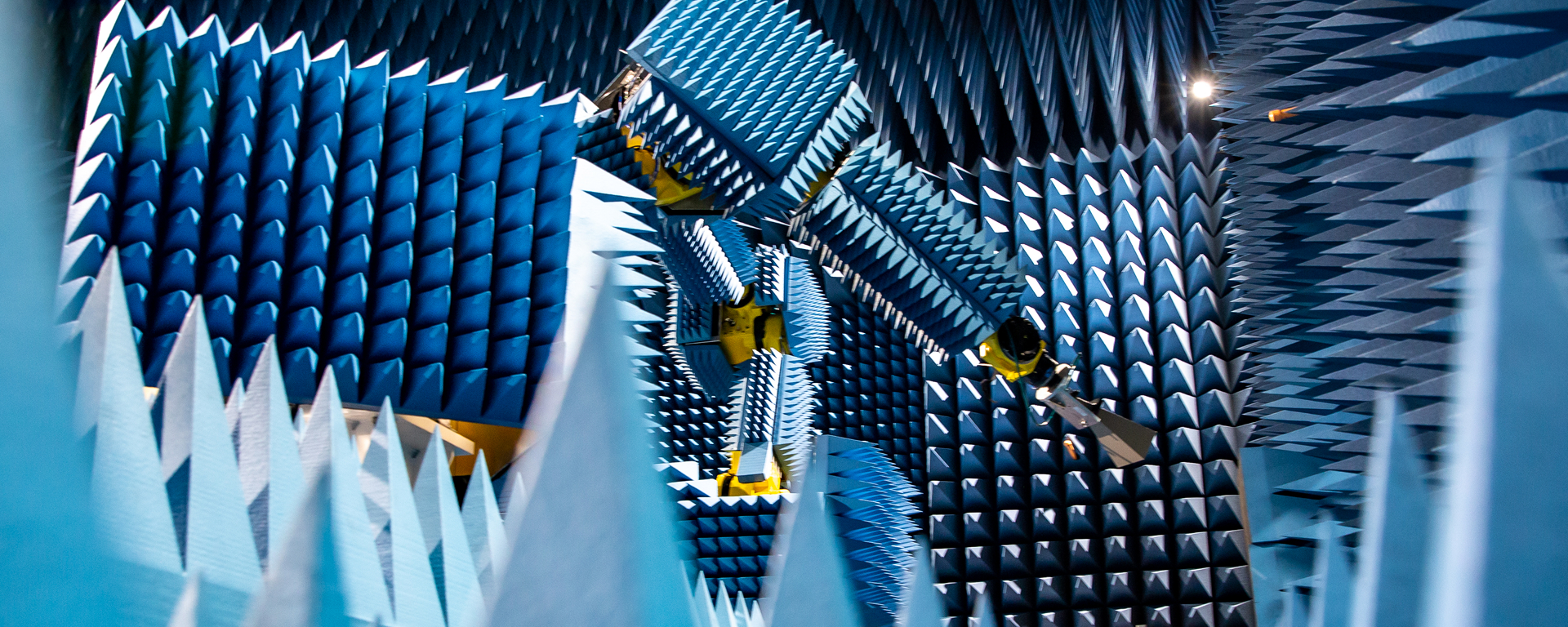

Autonomous Capabilities

With more than a century of aerospace experience, we have the opportunity and responsibility to ensure the next century of flight is safer than the first. Boeing is uniquely positioned to deliver a holistic approach to automation and autonomy solutions for aerospace. Our primary interest in autonomy is to improve the safety of our products.

To address the growing challenges of sustainable, economical and accessible modes of transportation, we are re-imagining the future of flight and mobility. Boeing is focusing on emerging technologies, unmanned aircraft systems (UAS) operations and the safe introduction of these vehicles into the airspace—while preserving the flying public’s confidence in air travel. See our Concept of Operations for Automated Flight Rules (AFR) for both crewed and uncrewed aircraft operations.

We’re investing in the future by developing technology in key areas such as Smart Factory, human-robotics collaboration and technology-enabled quality systems to enable breakthrough transformations across our production system.

Digital Transformation

Boeing has launched a coordinated and integrated approach to all digital efforts to support our next suite of products within a digital ecosystem. The comprehensive digital environment provides stability and predictability and will allow new products, production systems including the supply chain, and the support system to be designed together.

It is an enterprise effort that will shape how we design, build, test and service products far into the future. Model-based engineering production systems will be designed with the same engineering rigor as the airplane itself. This allows us to see how a change in one affects the other and better predict the performance of both.

Our goal is to establish a new paradigm for aerospace manufacturing and ultimately flatten the traditional notion of a learning curve.

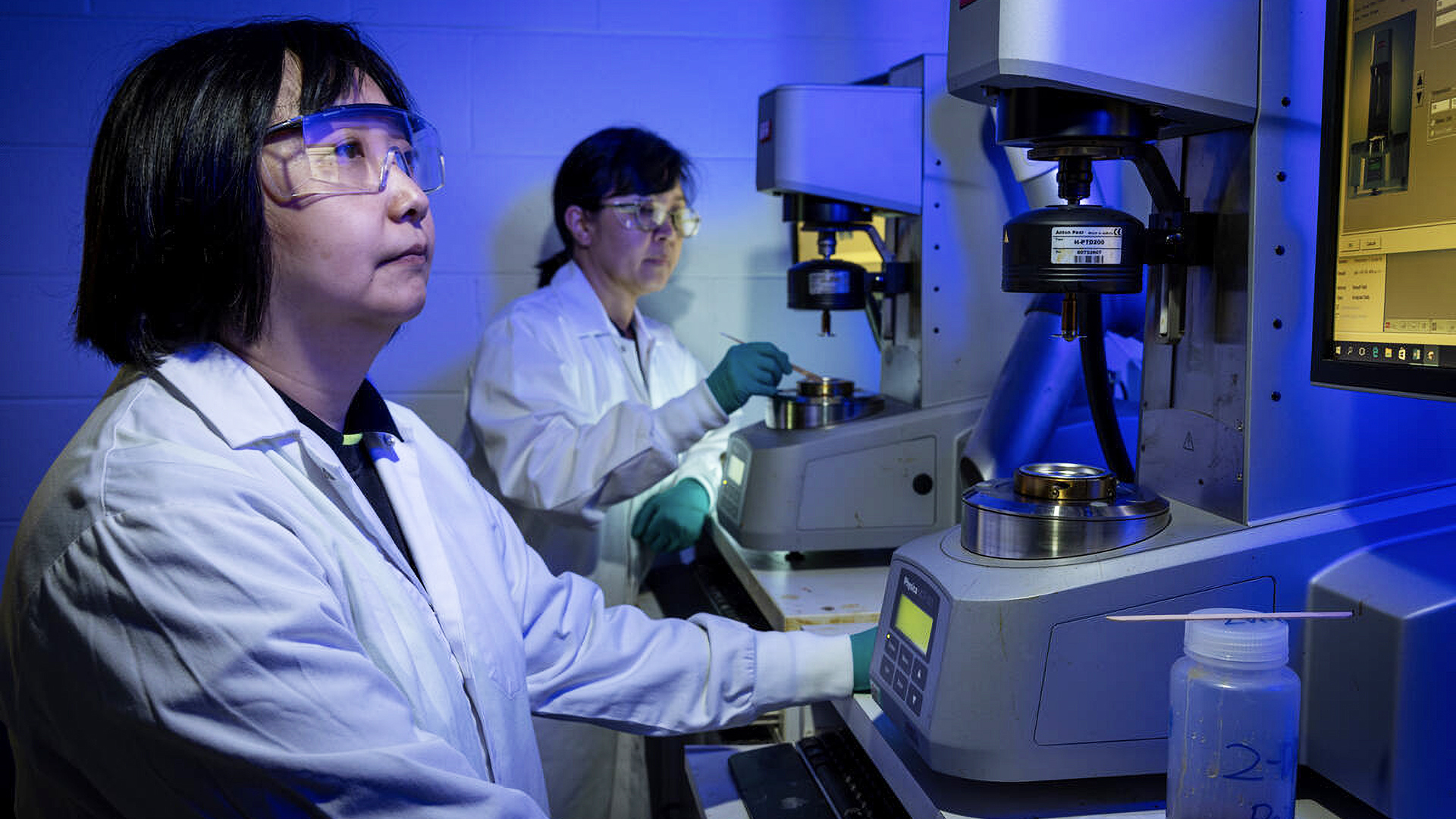

Producibility

Boeing’s work in producibility rests on the foundation of our decades-long investment in composite materials and manufacturing. We are embracing and investing in digital innovation and advanced manufacturing techniques to strengthen our production system, deliver on our commitment to quality and safety, and harness productivity enhancements.

We’re investing in the future by developing technology in key areas such as automation, Smart Factory, human-robotics collaboration and technology-enabled quality systems to enable breakthrough transformations across our production system.

We’re committed to leveraging technologies that reduce tedious manual tasks and capture rich, real-time data in order to improve safety and quality, while ushering in new advanced techniques, processes, tooling and systems.

Sustainability

Innovating for Sustainable Growth

Boeing collaborates globally with customers and stakeholders to support responsible growth for our industry, and we invest in innovation that improves the efficiency of air travel and our operations.