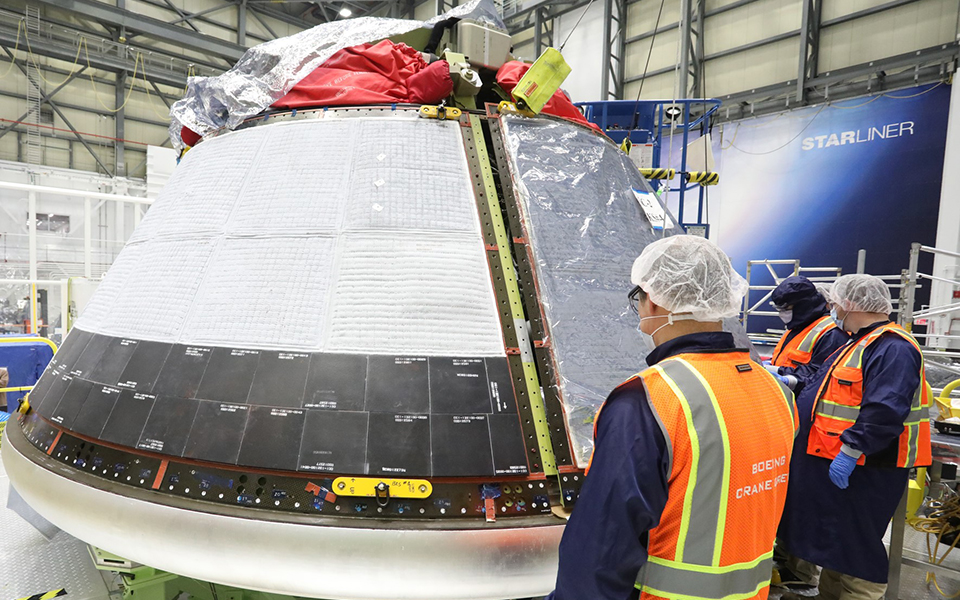

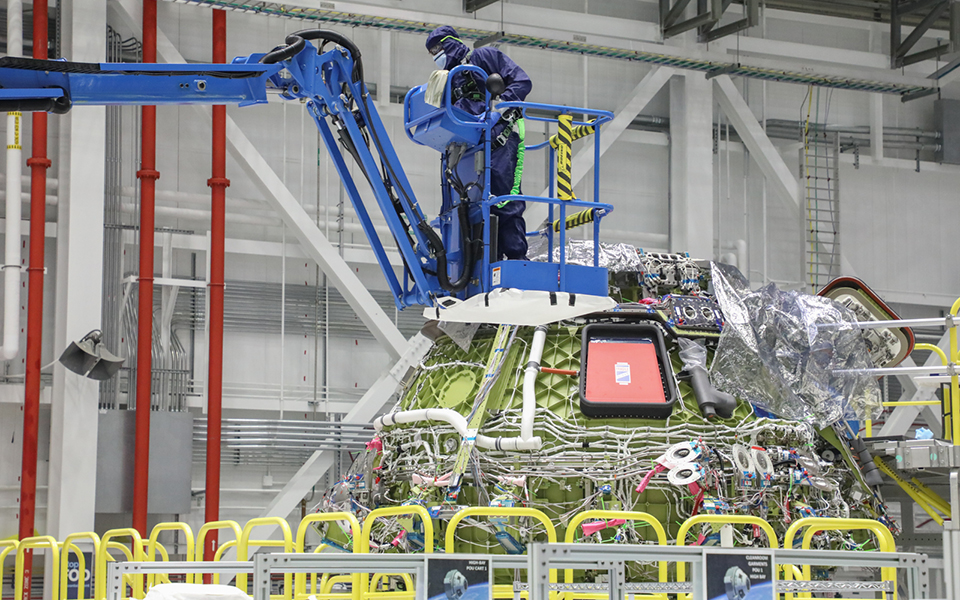

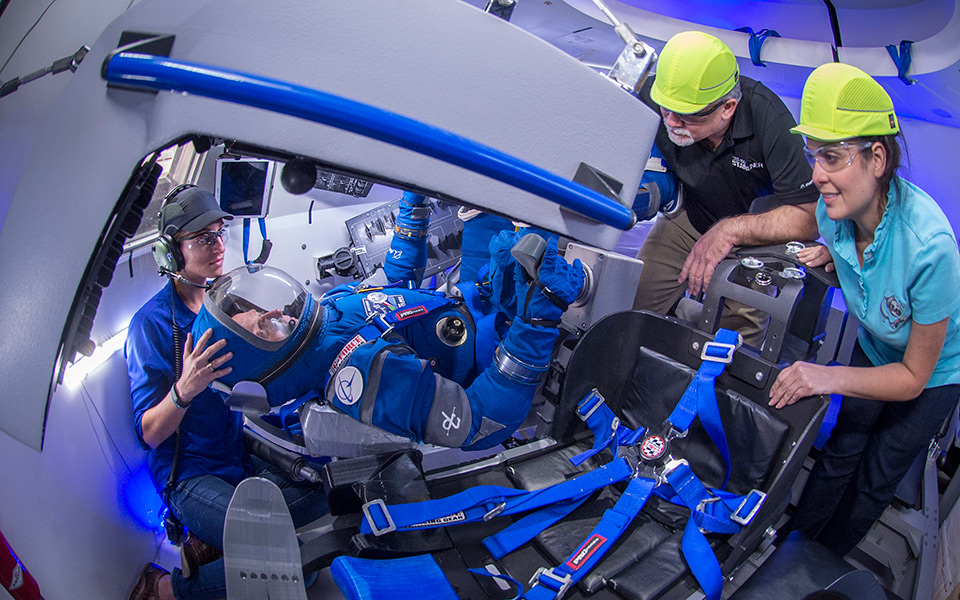

Boeing's Crew Space Transportation (CST)-100 Starliner spacecraft is being developed in collaboration with NASA's Commercial Crew Program. The Starliner was designed to accommodate seven passengers, or a mix of crew and cargo, for missions to low-Earth orbit. For NASA service missions to the International Space Station, it will carry up to four NASA-sponsored crew members and time-critical scientific research. The Starliner has an innovative, weldless structure and is reusable up to 10 times with a six-month turnaround time. It also features wireless internet and tablet technology for crew interfaces.

A 21st Century Space Capsule

Feature Stories

#Starliner Social Media

Gallery

- Image 2

- Image 3

- Image 4

- Image 5

- Image 6

- Image 7

- Image 8

- Image 9

- Image 10

- Image 11

- Image 12

- Image 13

- Image 14

- Image 15

- Image 16

- Image 17

Customers

The Starliner is setting the foundation for commercial passenger spaceflight services to and from low-Earth orbit. NASA is Boeing's anchor customer for the Starliner, beginning with missions to the International Space Station carrying NASA and NASA-sponsored crew members.

Quick Facts

- The Starliner is a reusable spacecraft that combines a proven capsule architecture, materials and subsystem technologies with 21st century innovations.

- The Starliner’s economic impact can be seen across the United States, with more than 425 suppliers in 37 states.

- The pusher abort system provides safe crew escape throughout the launch and ascent phase of the mission.

- Wireless internet will assist with crew communication, entertainment and docking with the International Space Station.

- An innovative weldless design eliminates the structural risks of traditional welds, and it also reduces mass and production time.

- Boeing-developed training devices provide Starliner crews extensive training on the most technologically advanced, proven and integrated systems, ensuring astronauts learn how to handle any situation that could arise in the harsh environment of space, even with a spacecraft that is designed to be autonomous.

- In addition to both an uncrewed and a crewed flight test, NASA has ordered six Boeing crew rotation missions to the International Space Station aboard the Starliner, which will be Boeing's first commercial human spaceflight missions.

- Starliner’s crew access tower is the first new access tower to be built along Florida’s Space Coast since the Apollo era. The crew access arm and white room, which are about 169 feet (51.5 meters) above the launch pad surface of Space Launch Complex 41, are where crews will begin boarding the Starliner before launch.

- Space Launch Complex 41 has been used only for non-crew spacecraft to this point, hosting Titan rockets beginning in 1965 and then the Atlas V since 2002. Notable NASA missions launched from the Starliner launch pad include the Viking robots that landed on Mars, the Voyager spacecraft that toured the outer planets, the New Horizons probe that flew past Pluto, and the Curiosity rover currently traversing Mars.

Wallpaper Downloads

Terms and Conditions of Image Use

Applying Wallpaper:

- Click on the screen resolution link you would like to use below. (A high-resolution bitmap image will appear in your browser.)

- Right-click on the image (control-click on a Mac)

- Select the option 'Set the Background' or 'Set as Wallpaper' (or similar)

Android download sizes:

320 x 480

1440 x 2560

1920 x 1080

BlackBerry download sizes:

Q10 720 x 720

Z10 768 x 1280

Z30 720 x 1280

iPhone download sizes:

iPhone 5 640 x 1136

iPhone 7 750 x 1334

iPhone 7 Plus 1242 x 2208