Above: The VERA flight-test team proved the effectiveness of the new tool. Back row, from left: Adam Bergamini, Roger Friedman, Darren McDonald, Capt. Jennifer Henderson, Capt. Christopher Caps, Emily Stednitz, Vanesa Miksa and Daniel Serna. Front row, from left: Taylor Manyrath and Dulnath (Dunes) Wijayratne. (© Boeing photo)

Flight test insights go real time

Teammates create new visual displays so pilots instantly know in flight if they have achieved test parameters.

Imagine needing to hit exact marks but not having real-time access to data that would let you know if you were doing so. That has been the reality of flight testing for Commercial Airplanes for decades — pilots had no way to know if they were achieving the required G-forces, bank angles or other parameters until they had completed each test maneuver.

Boeing engineers and pilots have created new display graphics so test pilots can see their results as they fly, allowing them to improve first-time completion of test objectives from 70% to 85% — with a plan to get even better.

Capt. Christopher Caps, 777X project pilot, and Capt. Jennifer Henderson, BCA chief pilot, proved the tool’s effectiveness during precision maneuvers on the third 777-9 test airplane (WH003) earlier this year.

The Visually Enriched Rendering Application (VERA) demonstrated its value immediately. VERA (learn more about the inspiration for the name) provides flight-test pilots with a visual display of flight parameters not needed for traditional operations.

- "VERA will change how we execute flight-test maneuvers. I can spend more effort focusing on flying the maneuver,” said Caps, who serves as lead pilot on the project. “Before VERA we had to memorize tolerances and safety limits and rely on scattered information. Now VERA fuses all that extra information in an organized and intuitive pilot display.”

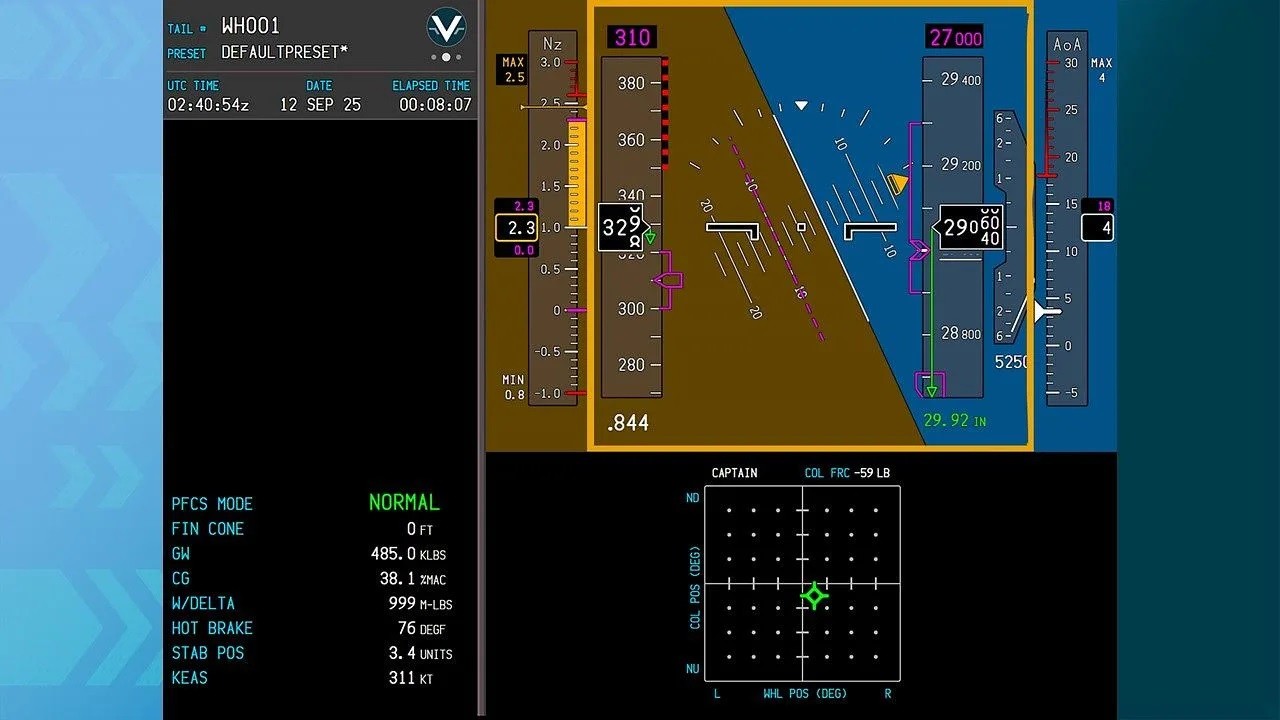

New data displayed using VERA surrounds a traditional flight display (inside the highlighted box) and gives flight-test pilots additional awareness during extreme maneuvers to ensure they meet exacting targets. (© Boeing photo)

To evaluate the new display features, Caps and Henderson had to perform steep turns, roller-coaster-like 0.5-1.5G oscillations, and approach to stall — a sampling of maneuvers all test programs are likely to encounter.

- “I felt like the airplane was safely enclosed in a box with boundaries. I love it,” Henderson said. “VERA is a game changer.”

The journey

The VERA tool took experts from Boeing Test & Evaluation, Boeing Germany and BCA Product Development nearly three years to complete.

Testing alone took nearly two years in simulators that provide the first level of operational testing of new systems and other flight deck equipment.

More than a dozen Boeing pilots went through human factors evaluations to determine if they were more efficient with VERA. There was improvement in every category measured — including pilot situational awareness, comprehension of the airplane’s current situation, and the pilot’s projection of the future status of the airplane.

By the numbers

Before VERA, the first-time success rate for conducting flight-test maneuvers was consistently at about 70%, meaning 30% of tests had to be repeated — straining budgets and schedules.

Boeing Defense, Space & Security demonstrated the benefits of a similar flight-test aid, which included a set of automated limiting functions. They achieved a 98% success rate. The first version of VERA will increase the BCA success rate to 85% and is expected to achieve closer to the 98% level with future enhancements.

- “We knew Commercial Airplanes could do the same and, in fact, could significantly expand on their concept,” said Roger Friedman, BCA Product Development engineer and Associate Technical Fellow.

How it works

VERA has a dedicated computer receiving data from the onboard flight-test data system and projecting the appropriate imagery to one of the airplane’s existing outboard flight deck displays, where it replaces the primary flight display.

The imagery is generated using custom software developed by Boeing Frankfurt, called RAPTOR-FD. Initially created to support rapid prototyping for flight deck displays, the Frankfurt team pivoted to support this new flight-test implementation. The result, according to project leaders, is an efficient capability that allows unprecedented customization for flight test use.

Imagery provided by VERA meets Boeing’s flight deck philosophy by providing better situational awareness and tailored feedback cues to the pilots in a familiar context. Flight-test pilots now have immediate feedback for the quality of precise flight-test data they are collecting.

Making it real

Now, pilots can activate VERA with the twist of a rotary switch. When selected, the existing primary flight display in front of the pilot is moved to the adjacent inboard screen, and VERA is displayed directly in front of the pilot. Tailored VERA features are available to help the pilot fly unique and complicated flight-test maneuvers.

“This is a safer way to flight test,” Friedman said. “We obtain the data we need more efficiently, which saves time and, consequently, money.”

Three of the 777-9 flight-test airplanes are equipped with VERA, and the 737-10 in flight test will be equipped within the year. VERA is also part of the baseline flight-test configuration for the future 777-8F test fleet.

When flight testing on these airplanes is complete, the process of removing VERA and the associated installations is done within the normal refurbishment process. VERA does not modify the airplane’s flight deck display software code or system and returns to standard configuration without extraordinary planning or effort.

VERA in action with Capt. Jennifer Henderson (left) and Capt. Christopher Caps on board the 777-9. (© Boeing photo)

Ready for more

Built into VERA is the capacity to improve and expand functionality in the future. As airplanes become more sophisticated, and as testing protocol evolves, so will VERA.

- “We have a disciplined process for adding new capabilities,” said Technical Fellow and flight-test engineer Darren McDonald. “We have protections in place to make sure we don’t impact the integrity of other data, displays or the pilot’s perception of the airplane’s state.”

Preparing for the future is a step that today’s pilots appreciate.

- “Every new piece of information will have to be integrated in a way that helps performance,” said Capt. Caps. “Flight deck display design is all about what a pilot needs and what they can use without being distracted.”