Much like a surgeon performing a delicate operation, teams working in Boeing teardown labs carefully dissect aircraft components to uncover the keys to improved performance.

The process allows teardown engineers to collect important product data to design and build even greater efficiency at every stage of the production life cycle.

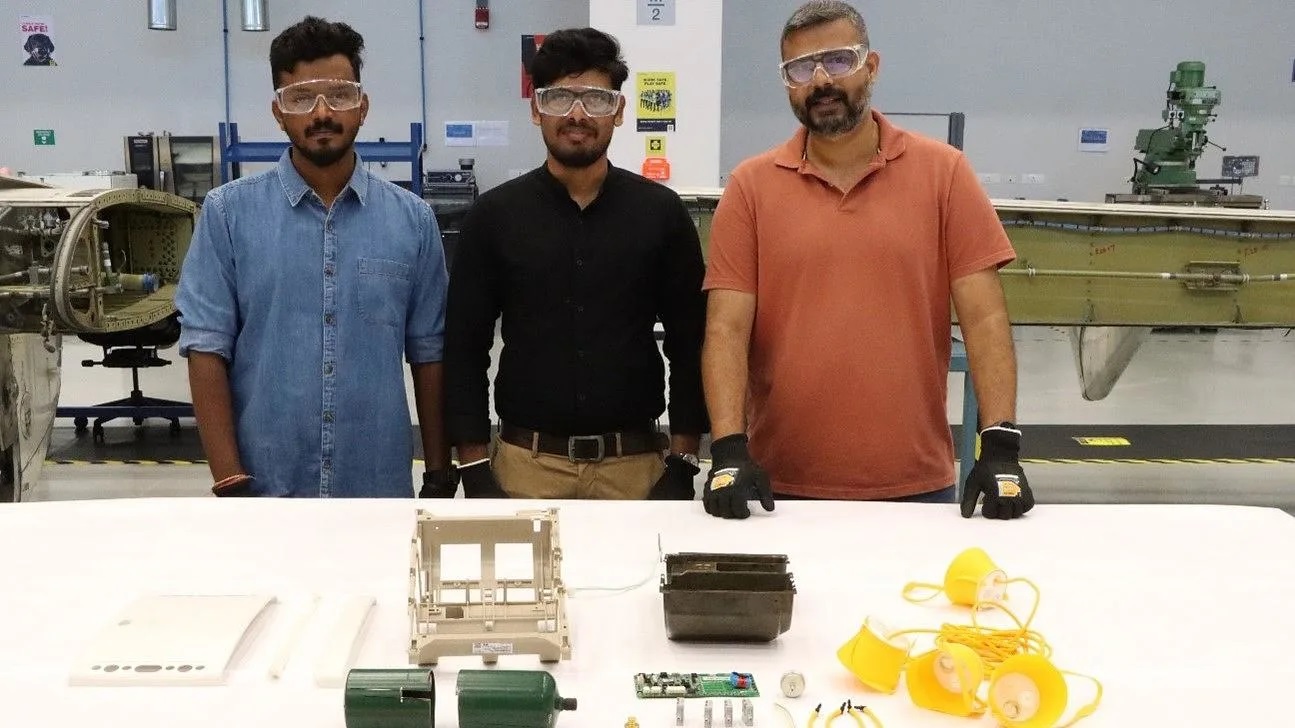

Across three Boeing Technology Innovation (BTI) teardown labs – in Bangalore, Seattle, and St. Louis – teams study competitor wings, fuselages, and systems, then share their findings across the company. Comparing Boeing products with those of competitors offers insights into distinctive design alternatives.

The labs have contributed to enabling more than $2 billion in cost mitigation and savings through optimal cost and design recovery.

The benefits:

- Increases savings for Boeing and customers — Understanding how a product functions enables comparative analysis and benchmarking against off-the-shelf parts.

- Promotes more efficient design — Allows engineers to refine product design capabilities earlier in the process.

- Empowers contract bid negotiations — Facilitates discussions based on actual data, effectively curbing price creep of components during bid proposals.

Why it matters: “Teardown labs are essential for driving innovation, cost savings, and competitive advantage, all while ensuring that innovations meet the highest safety standards,” said Syamalarao Gude, Teardown Lab capability leader. “As Boeing advances aerospace technology, the teardown labs drive informed decision-making and promote continuous improvement across the enterprise.”