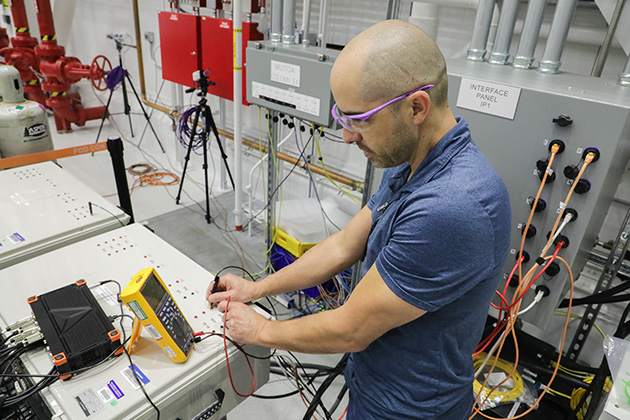

Test engineer Marcelo Blalock still can visualize visiting his dad’s workplace at Kennedy Space Center in high school and being in awe of the hardware in a lab that certified sensors, transducers and other equipment for shuttle launch support.

Little did he know, he’d be working years later as an adult with his father on a NASA contract at KSC for six years and then later on the CST-100 Starliner program for about eight months before his dad retired in 2018.

“I really look up to my dad and in my mind he’s one of the most brilliant people I know. To be able to work with him and see him in action was fantastic to me,” Marcelo said. “It’s a life experience I’ll never get again, but will always be ingrained in my memory.”

Marcelo and his dad, Norman “Mike” Blalock, a former engineer with McDonnell Douglas and Boeing as well as a manager with other aerospace companies, worked in the engineering development lab on numerous projects toward the end of the space shuttle program and provided support for the Constellation program and the Space Launch System ground system development. Mike said he was proud of his son, who became the “go to” guy when seeking a viable solution in an efficient manner.