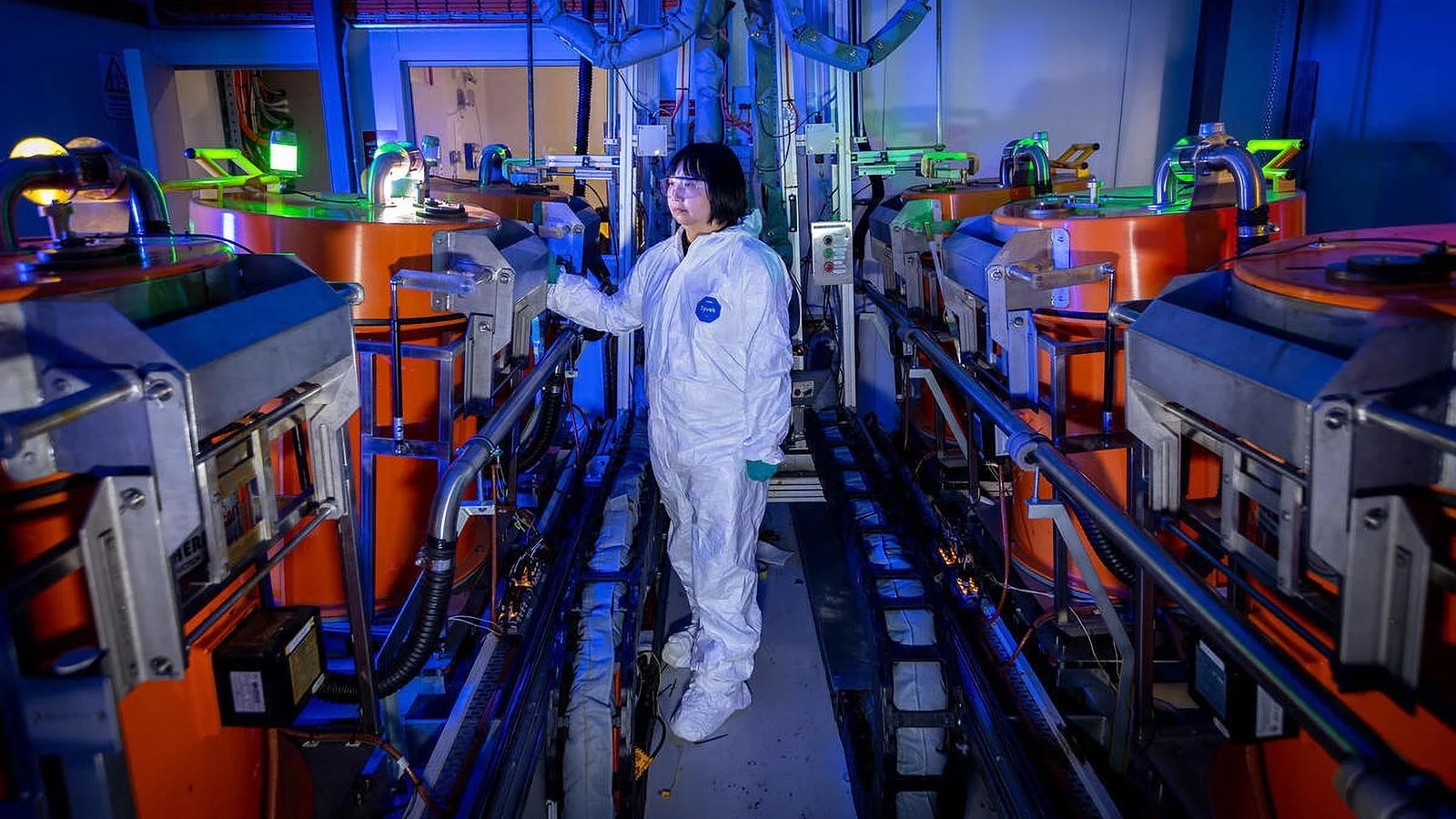

Tian’s radial braiding research explored potential advancements of dry materials, creating a foundation on which to build on the balance of toughness and strength. She completed her doctorate in 2022 at RMIT University through Boeing’s Learning Together Program, which provides tuition assistance for company employees. Her findings will help engineers consider the right application of advanced braid formats in the future.

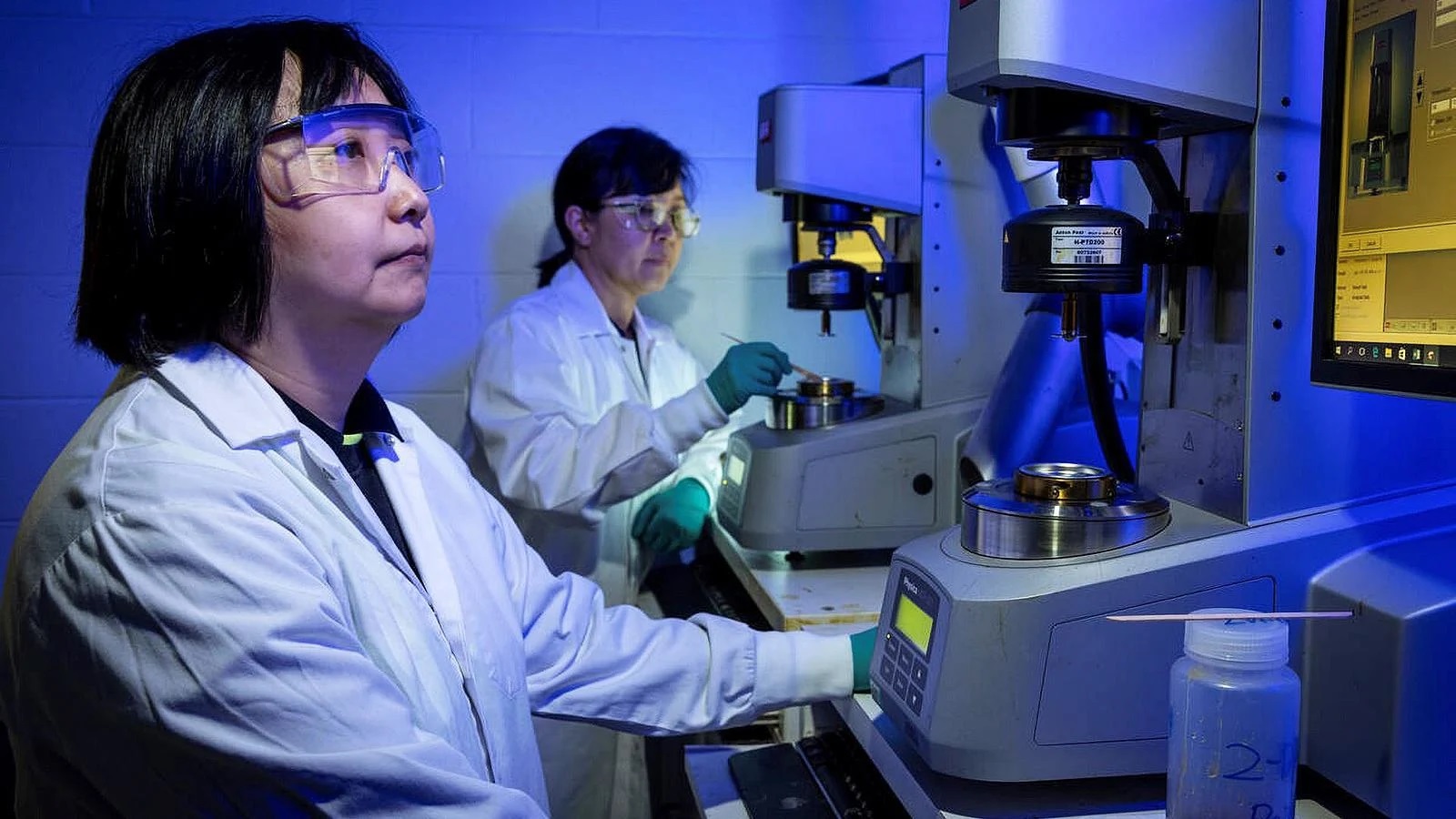

“Since completing my doctorate, I’ve focused on reducing the time required to infuse and cure a part,” said Tian, estimating a 30% time reduction.

“I’m also part of a team working on an automated mixing system, which will enable production teams to mix resin locally and safely deliver resin to the production line on demand.”

Premixed resin falls into a class of dangerous goods that cannot be transported by air. Stored in special containers at minus 18 degrees Celsius, the resins must be transported by boat. Shipments can take two months, and the resin must remain in storage at minus 18 C after arrival. Tian estimates the amount of energy used in transportation and storage to be 50 times the energy it takes to manufacture the composite part.

Mixing the resin on demand eliminates the need to transport and store the premixed resin. The components can be transported by air, at room temperature.

“The automated mixing system technology is expected to be implemented into production in Melbourne next year, and we have filed two patent discoveries,” Tian said.

“I love finding ways to make our processes better, and seeing it realized in production makes the effort worth it.”

By Sarah Schuiringa

Not subject to Australian Defence Trade Controls Act 2012