Above: James Cenance and Sean Stockfish insert load panels to the test article. (Liz Morrell photo © Boeing)

Sound check: Acoustic blanket mutes and protects moon rocket

Teams test sound-absorbing materials to shield propulsion systems for future Artemis missions.

Engineering teams have successfully completed development testing on a critical sound absorption component for Exploration Upper Stage (EUS), which will power future Artemis missions. The structural performance of the moon rocket’s interstage acoustic blanket was tested at NASA’s Michoud Assembly facility in New Orleans, Louisiana.

Why it matters: After launch, the Space Launch System (SLS)’s moon rocket will climb through the atmosphere towards orbit, with aerodynamic forces generating acoustic – or sound – energy within the interstage.

- If the sound levels are too high, it could affect the performance of the upper stage’s rocket engine, sensitive avionics and propulsion systems.

- To protect these systems, the interstage has special ‘acoustic blankets’ that absorb sound.

Above: The acoustic blanket is tested at various angles to provide insights into safety and design improvements. (Liz Morrell photo © Boeing)

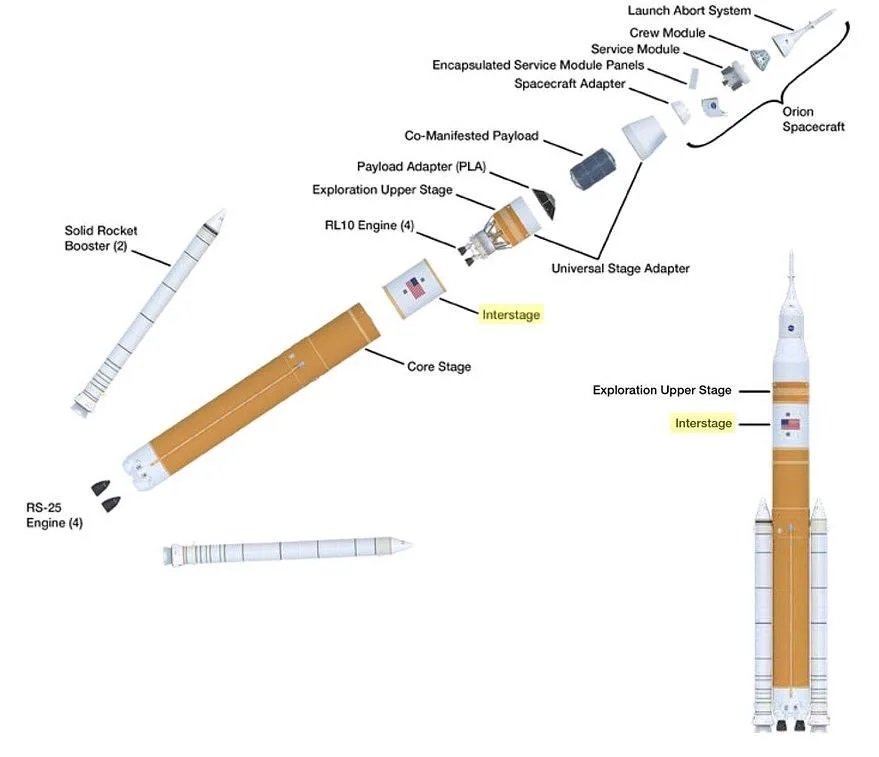

The interstage: The interstage connects the Exploration Upper Stage to the core stage of the SLS Block 1B rocket. The interstage shields the upper stage and its RL10 Engines from strong acoustic loads during ascent.

- After the Main Engine Cutoff (MECO) following launch, the interstage separates the upper stage and payloads from the core stage, allowing the EUS engines to ignite and propel the crew and cargo toward the moon.

Above: NASA Space Launch System Block 1B vehicle, with interstage pictured between core stage and the Exploration Upper Stage. (NASA illustration)

Testing it out: Engineering and manufacturing teams created a 1:1 scale model of the interstage using acoustic absorption materials which are flexible like sponges.

- They tested how these materials would behave during the rocket's ascent, collecting data on angles and movements to help inform the final design and safety factors.

- The manufacturing team also created guidelines to make the installation process of the acoustic blankets more efficient.

Left: Brooke Merenuk and Sean Stockfish inspect and measure the angles necessary to calculate safety factors for flight.

Right: Ryan Riviere, Jessica Corbett and Brooke Merenuk perform fit-up inspections for the pre-test condition.

(Liz Morrell photos © Boeing)

What comes next: Later this year the team will conduct additional tests using parts made by suppliers. These tests will validate the final design, which is based on lessons learned from the first round of testing. Following that, final qualification testing will ensure the system meets all requirements, allowing them to install dozens of acoustic blankets on the interstage for the Artemis missions.

Above: The EUS Acoustic Blanket engineering teammates, Sean Stockfish, Brooke Merenuk, Jessica Corbett, Ryan Riviere, are shown in front of the test article in the Michoud Assembly Facility EUS Gray Box Assembly area.