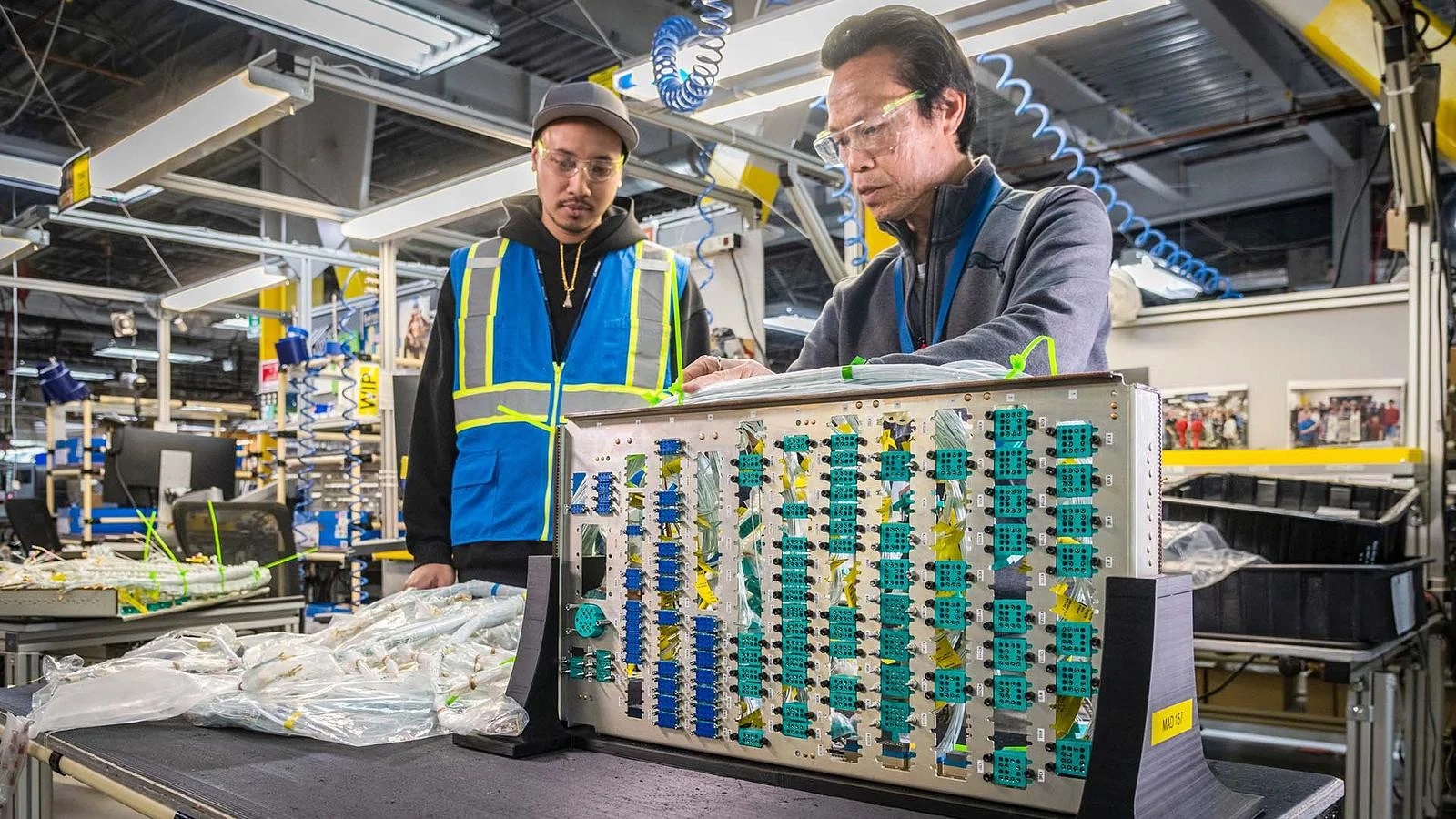

Why it matters: Improvements like this help eliminate defects, a pillar in the company’s Safety & Quality Plan.

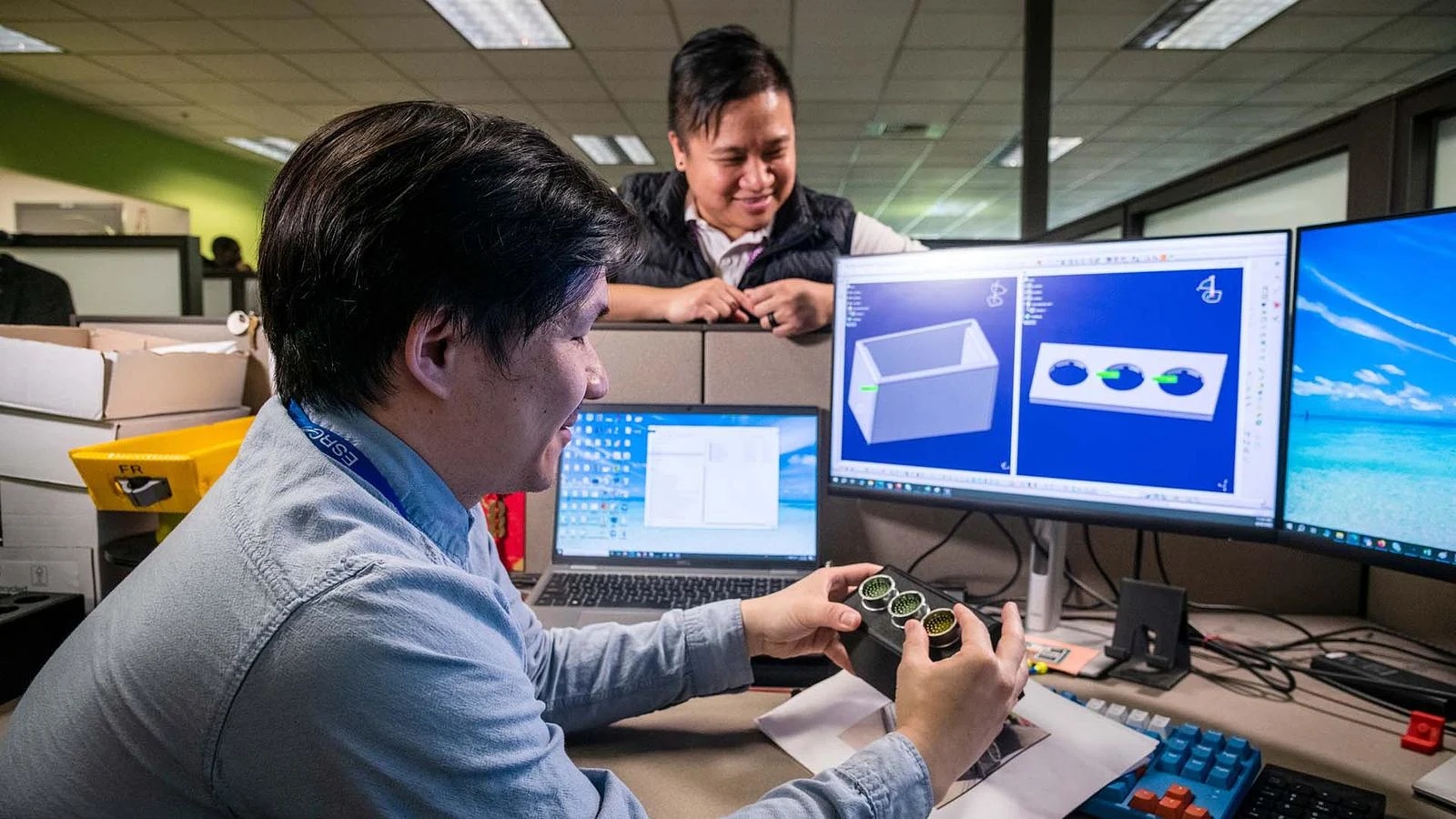

- “These quick wins can be replicated across our teams to help improve safety,” said Jia Huang the ESRC’s Factory Support Collaboration Center team lead who is helping shepherd this initiative. “Instead of waiting to order a part that may not work, we can create them based on direct feedback from our team.”

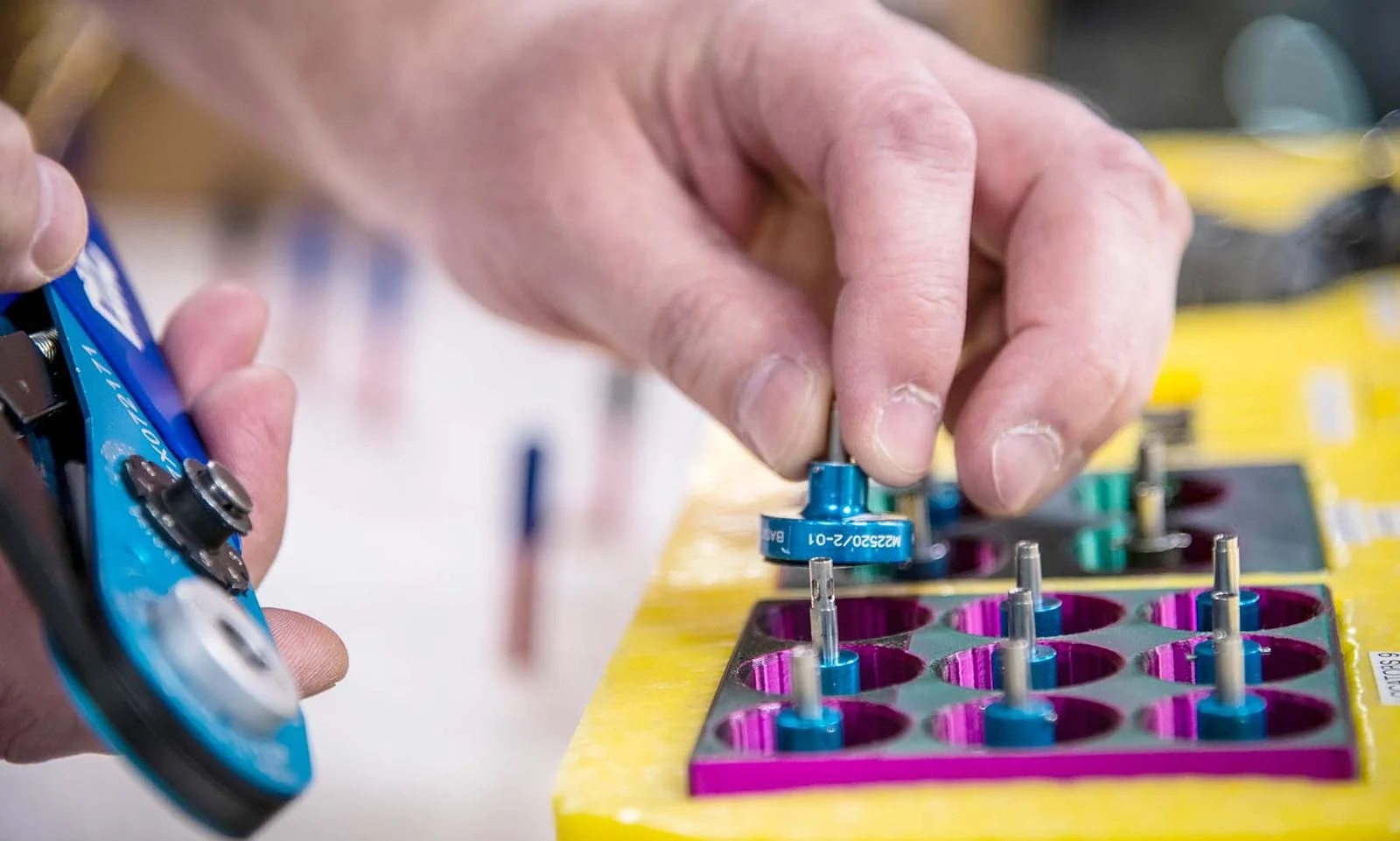

Designed in partnership: Each tool was developed in close collaboration with end users to ensure it met their needs and was validated by Engineering to ensure compliance.

- “As engineers, designs on paper might look perfect, but might miss the nuances in practice,” said Curtis Rodriguez Quamina, an electrical manufacturing engineer. “Therefore, if a tool is designed for a teammate, it makes sense to involve them in the process.”

Derik Ibay, an interim manager and Kaizen tech, echoed this sentiment. “Together we can create quality products in a quality workplace.”

The bottom line: “By working together, we can find permanent solutions to common problems,” said Alex Tran, a 767 Freighter team lead.