Built into every job

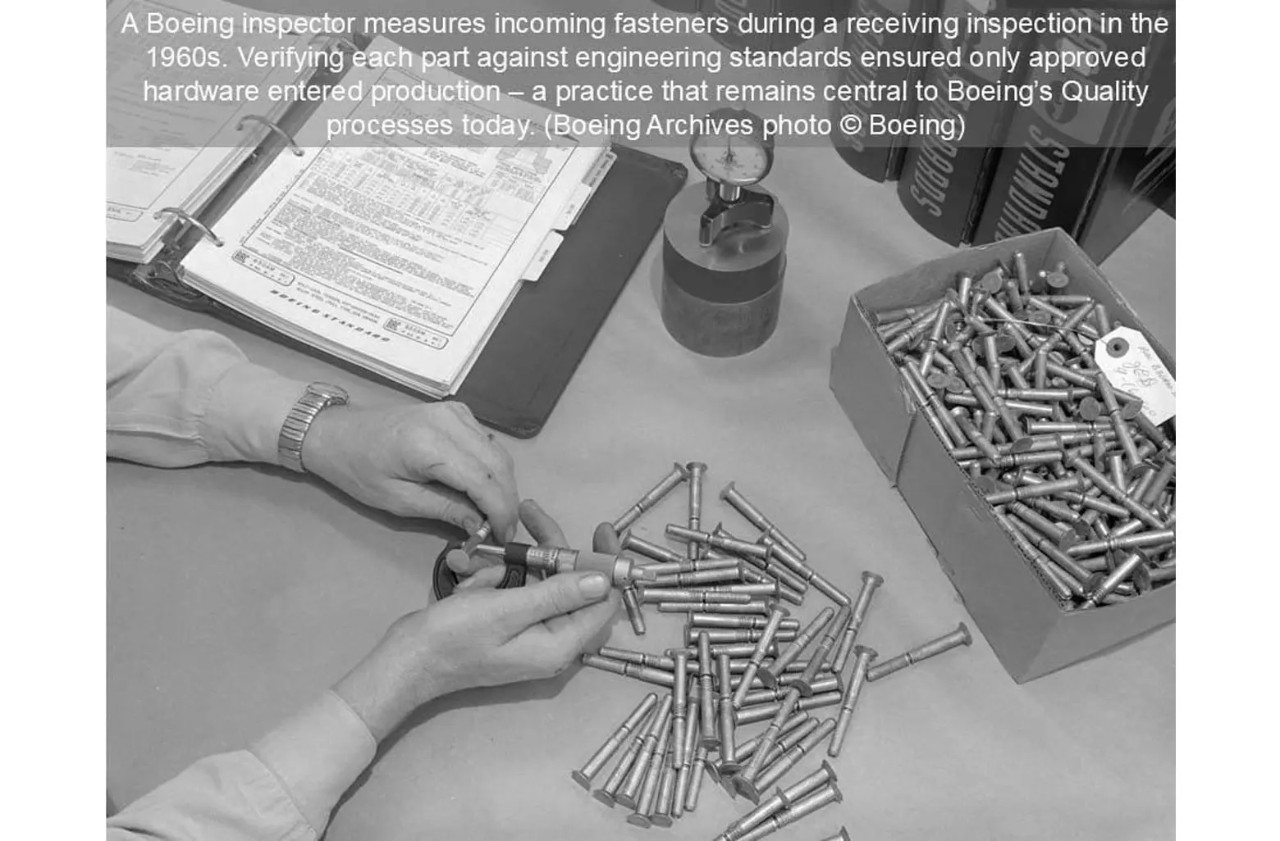

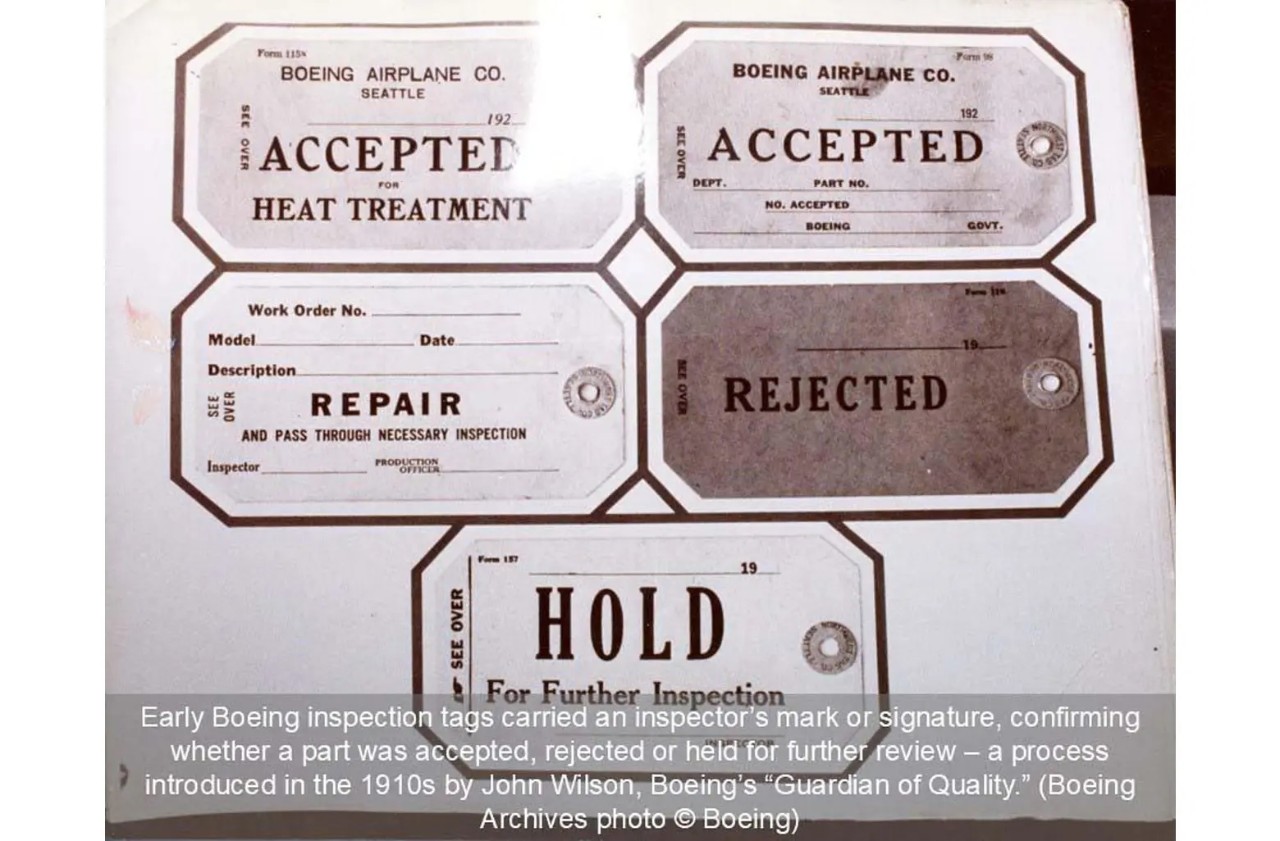

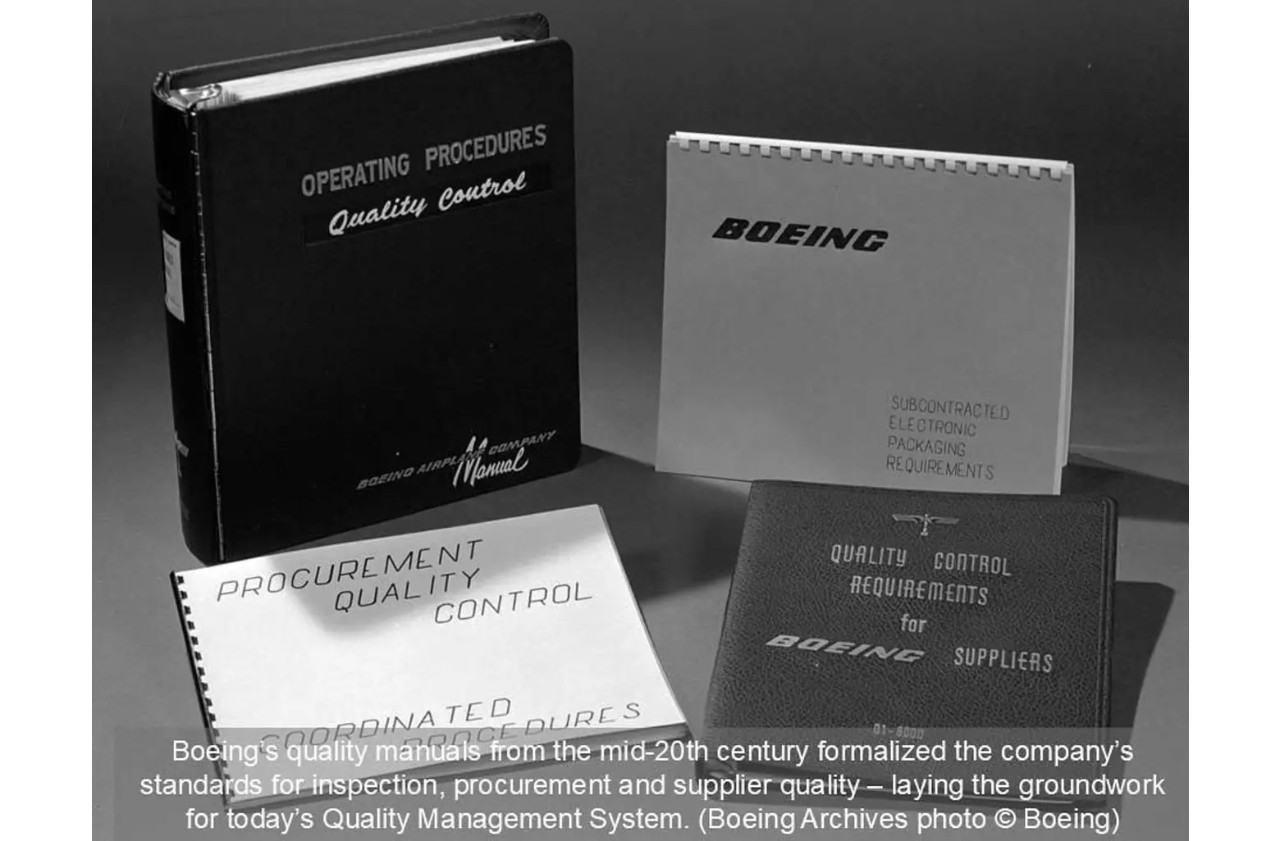

Until the 1940s, shop employees largely performed quality checks themselves. But by 1944, Boeing formalized those principles into its first Quality Department. One of its first managers, Elwood Kaiser, captured the philosophy that has lasted through the decades: “Quality cannot be inspected into our airplanes – it must be placed there by the individual employee,” he said.

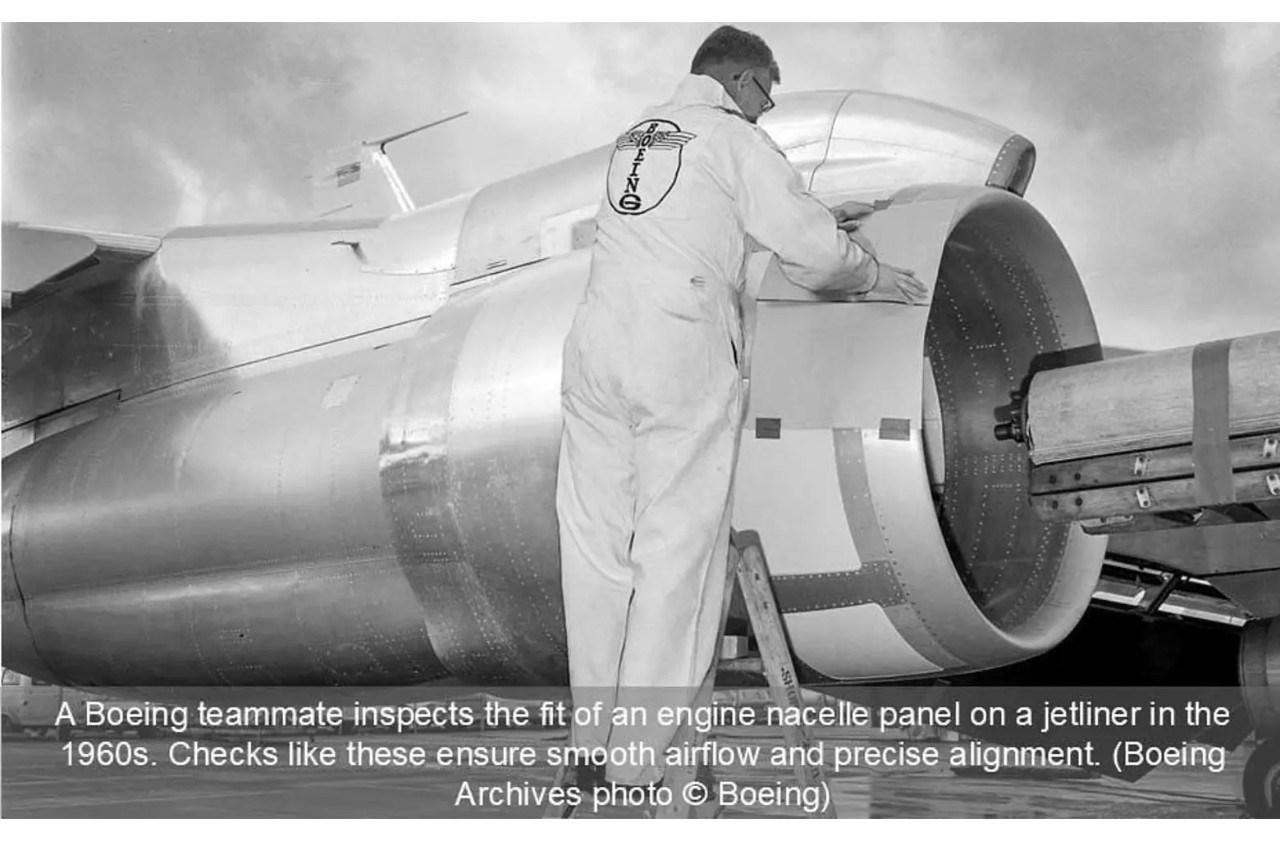

When production surged in the 1950s, as Boeing expanded from wartime manufacturing into the jet age, employees created the Quality Control Club to share ideas and prevent defects. Factory posters reminded teammates that “Quality means reliability” and “Every person’s job is vital to quality.”

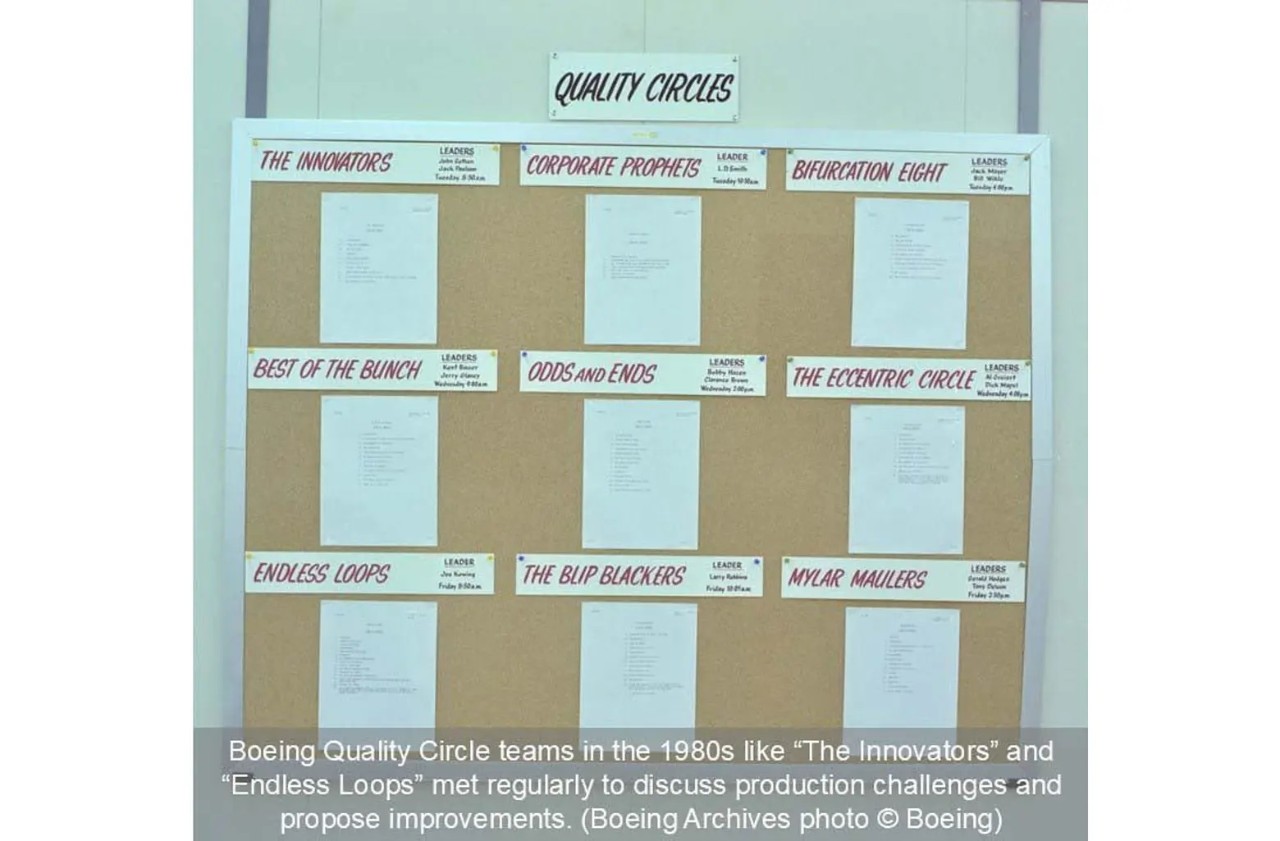

That spirit reemerged in the 1980s through Quality Circles – more than 600 employee-led groups met weekly to analyze issues and suggest improvements. Their ideas reduced rework, improved safety and quality, and strengthened Boeing’s reputation for precision.

- Today’s Employee Involvement Teams are similar, giving teammates across functions a structured way to share ideas – resulting in thousands of solutions that have improved safety, quality and efficiency.

In the 1990s, Boeing strengthened that foundation with systems like Lean manufacturing and the Quality Management System – part of an industry shift towards efficiency, consistency and customer focus.

- “Engaging our teams and listening to their feedback is foundational to lasting quality and continuous improvement,” said Kim Smith, vice president of Quality, Operations & Execution, Global Services. “When we own our work and share ideas, we deliver quality at every step, every time with the excellence and predictability our customers can depend on.”

Learning from challenges

As the company evolved, each decade brought challenges that tested but ultimately made its quality systems stronger.

Production slowdowns and mass layoffs in the 1970s led to workmanship issues that forced teams to rethink how they trained and supported mechanics on the floor.

By the 1980s, process gaps in defense programs prompted improvements to documentation and inspection processes.

Recent years brought more lessons through some of Boeing’s toughest moments – from delivery pauses in 2019 on the KC-46 tanker and 2021 on the 787 Dreamliner, to the 737 MAX grounding in 2019 and door plug accident in 2024. Each came with difficult reflection and significant change, including tighter inspections, clearer accountability and stronger links between Engineering, Manufacturing and Quality.

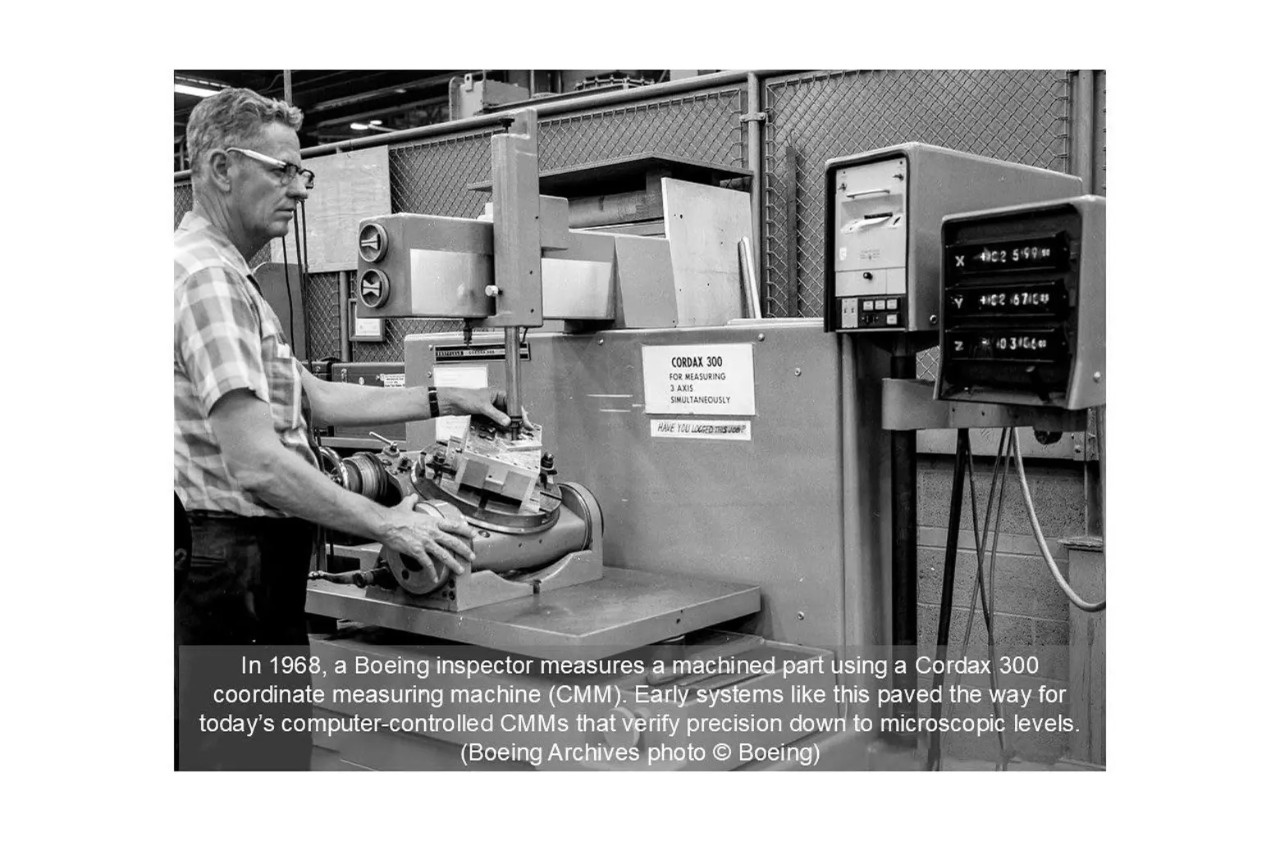

Over time, the experiences have shown how Boeing’s quality standards remain a constant, even as systems and tools evolve.

A legacy that endures

For more than a century, company leaders say Boeing has demonstrated a focus on quality, and a drive for improvement that continues today.

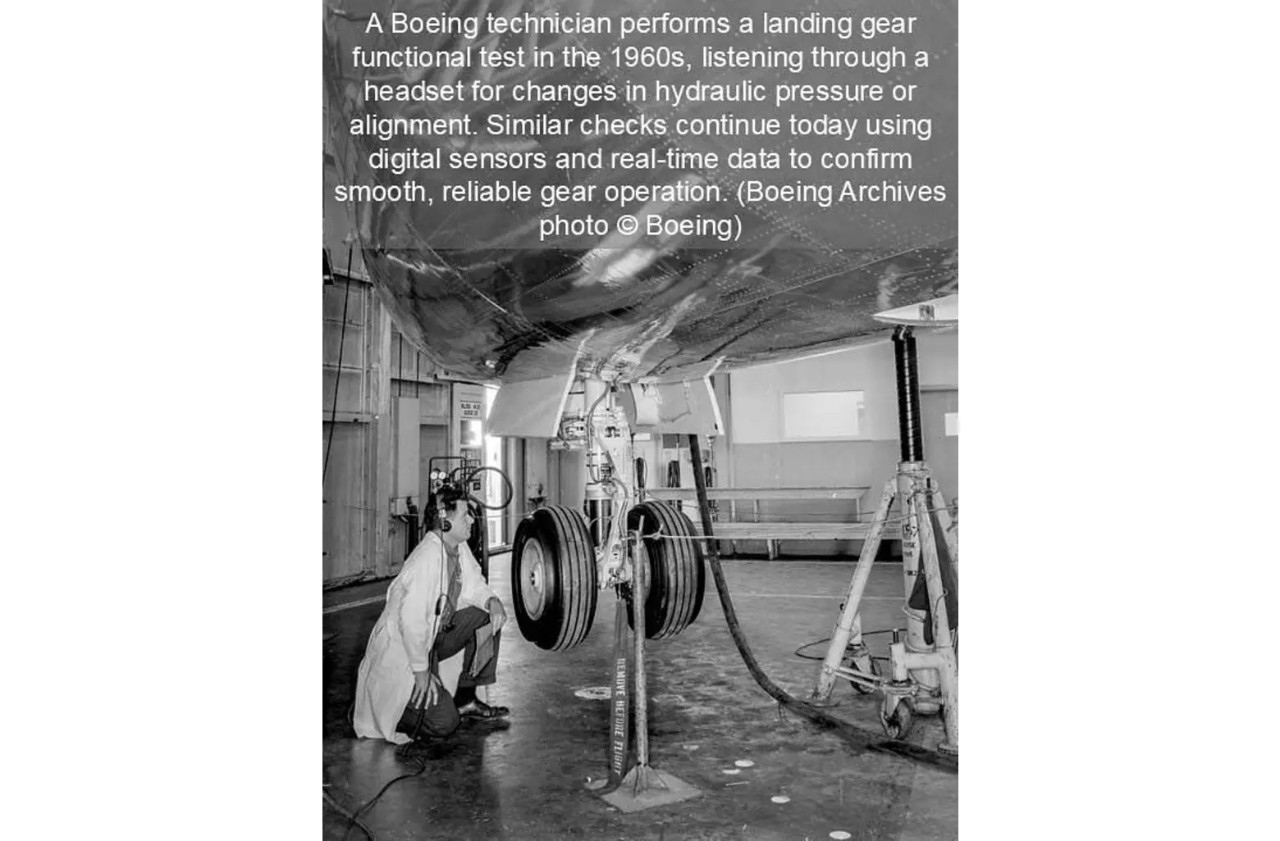

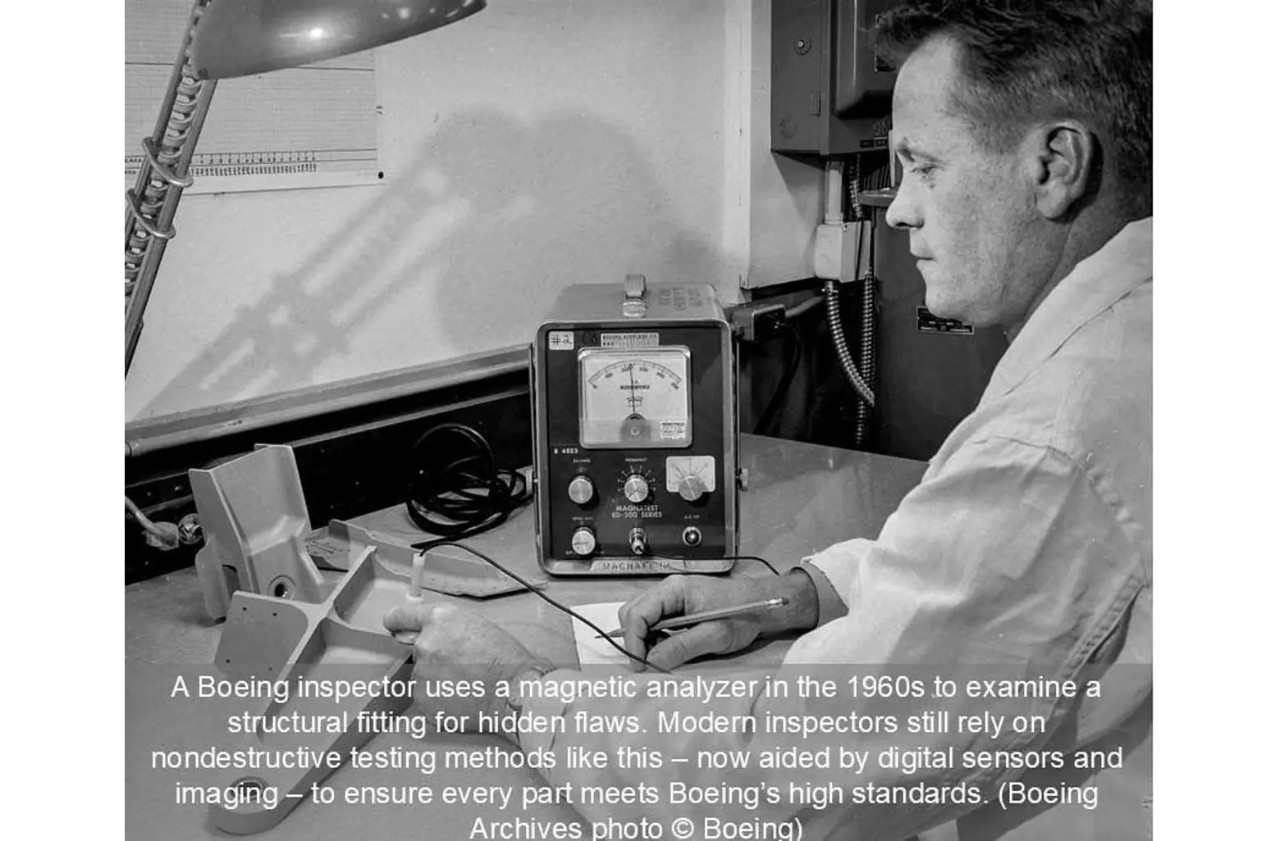

Teams are rewriting and simplifying thousands of decades-old procedures, and using digital tools to improve training and work instructions. Improvement plans based on data from inspections and supplier feedback are also helping teams spot trends and fix issues faster.

- “It’s up to each generation to meet the high bar set by our founder,” said Marisela Reyes, vice president of Quality and Lean for Defense, Space & Security. “Yes, our systems and processes evolve to leverage modern demands and technology, but our standard for quality is absolute.”

The big picture: November is World Quality Month. Boeing joins quality organizations across the globe during this annual opportunity to share progress and best practices.