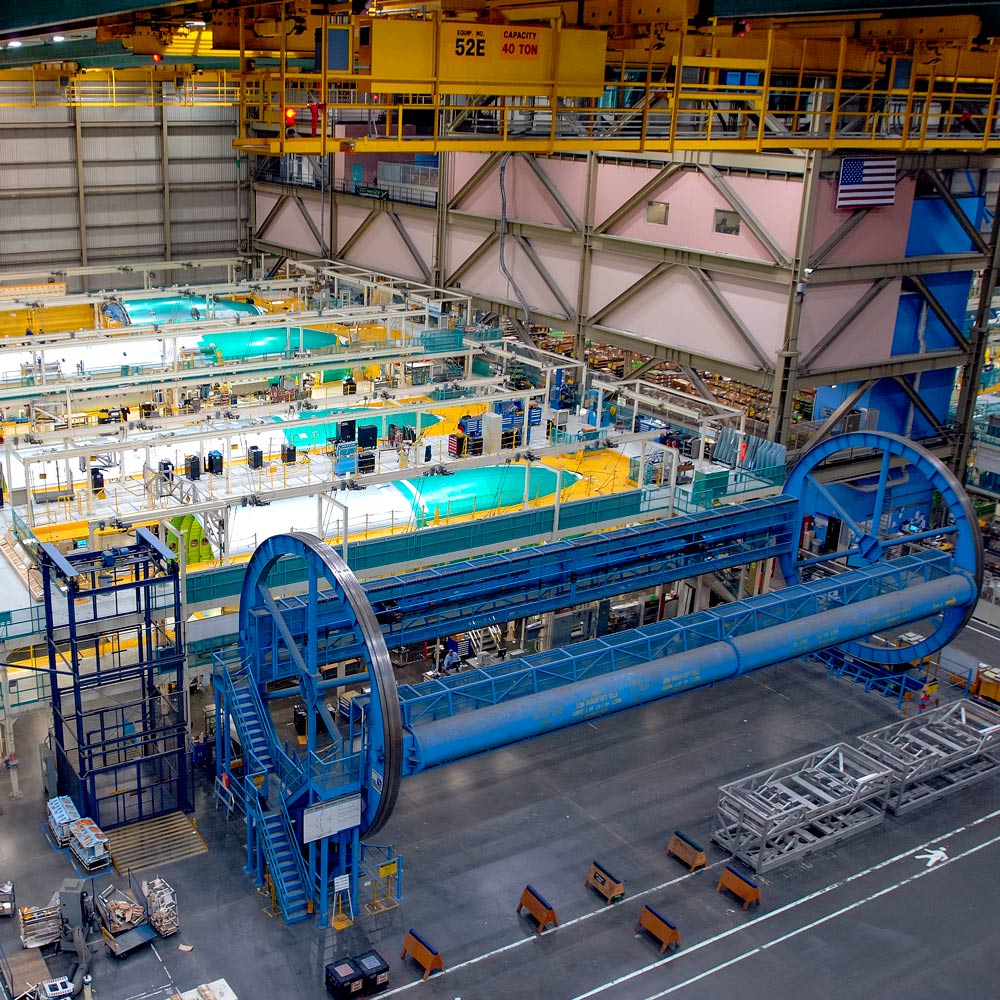

Boeing began planning to incorporate determinant assembly for 777 fuselages in 2013, as part of an initiative to improve workplace safety and quality in fuselage assembly. Known as fuselage automated upright assembly (FAUB), the effort also incorporated automated, guided robots to drill and install approximately 50,000 fasteners that had traditionally been done by hand. Boeing incorporated the changes in a portion of the Everett factory in 2015, fully implementing it in production by year end, under FAA oversight.

After careful evaluation, in mid-2019 Boeing began changing the type of automation in the assembly of the forward and aft fuselage sections from robots to flex tracks. First developed by Boeing Commercial Airplanes, flex tracks are an automated drilling technology proven effective on commercial programs such as the 787 Dreamliner and defense programs as well as in the later stages of assembly of the 777. Mechanics attach flexible tracks spanning the fuselage skin, then numerically controlled drills ride along the tracks to drill holes while the mechanics manually attach fasteners on the inside. The decision to change approaches, under FAA oversight, was driven by experience that showed flex tracks deliver higher quality, requiring less work by hand and with higher reliability, than what the robots had been capable of in the forward and aft fuselage areas.

Before the decision was made to implement flex tracks, the 777 program redesigned portions of the build process with rivets and less difficult forms of fasteners. Taken together, those changes and the flex track solution improved both safety and quality over the robot technology in forward and aft as well as the pre-2015 production process.

While this change sometimes is referred to as the discontinuation of FAUB, it’s notable that 777 fuselage sections are still built using automation and determinant assembly, though it is through modified means. Boeing also continues to use autonomous robotic technology to assemble the mid-fuselage section of the 777 and in other portions of production, including at the Composite Wing Center, where certain 777X wing components are fabricated, and on the Horizontal Build Line, where 777X wings are assembled.

All of these applications were implemented following the same careful assessment, rigorous review and FAA oversight, and all are performing to specification, producing assemblies that achieve quality expectations and conform to design requirements.