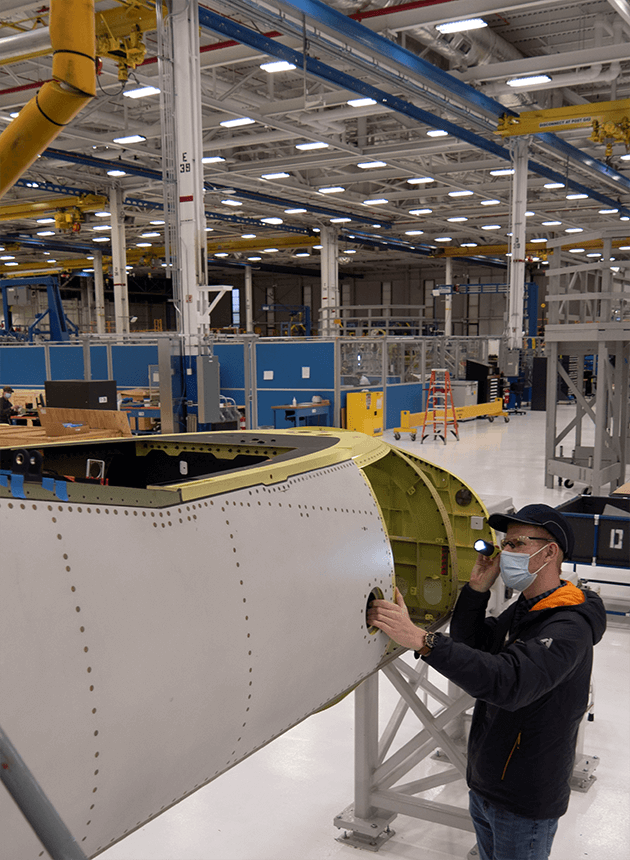

A new era in aircraft design and assembly has begun as the first U.S. portion of the Boeing-Saab eT-7A Red Hawk advanced trainer officially entered the jet’s state-of-the-art production line. Once delivered to the U.S. Air Force, it will carry the name the T-7A Red Hawk.

The training jet was fully designed using 3D model-based definition and data management systems developed at Boeing during the last two decades.

The T-7A Red Hawk has employed the digital engineering and design of the Boeing T-X aircraft that went from firm concept to first flight in just 36 months for the U.S. Air Force Advanced Pilot Training competition.

“The future of air dominance lies in the ability to move quickly, take smart risks and partner in new ways to get the job done,” said Shelley Lavender, senior vice president, Strike, Surveillance and Mobility. “By creating aircraft and systems along a digital thread, we can accelerate build times and increase quality and affordability for our customers in a way that has never been done before.”