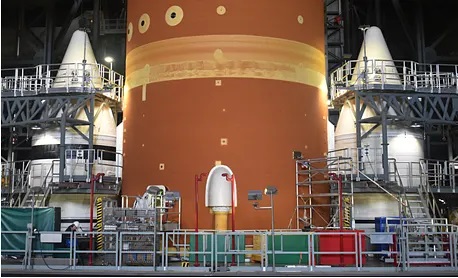

The Space Launch System rocket, with Boeing-designed metal strakes now in place, is preparing for rollout at Kennedy Space Center in Florida. (© Boeing)

When the Artemis II moon rocket rolls out to the launch pad, you may notice it’s rocking some new hardware designed by Boeing to improve airflow. After the successful Artemis I launch in 2022, Boeing and NASA evaluated post-flight data and discovered the Space Launch System (SLS) rocket faced higher-than-expected vibrations near the solid rocket booster attachment points.

The cause? Unsteady airflow in the gap between the core stage and the two solid rocket boosters.

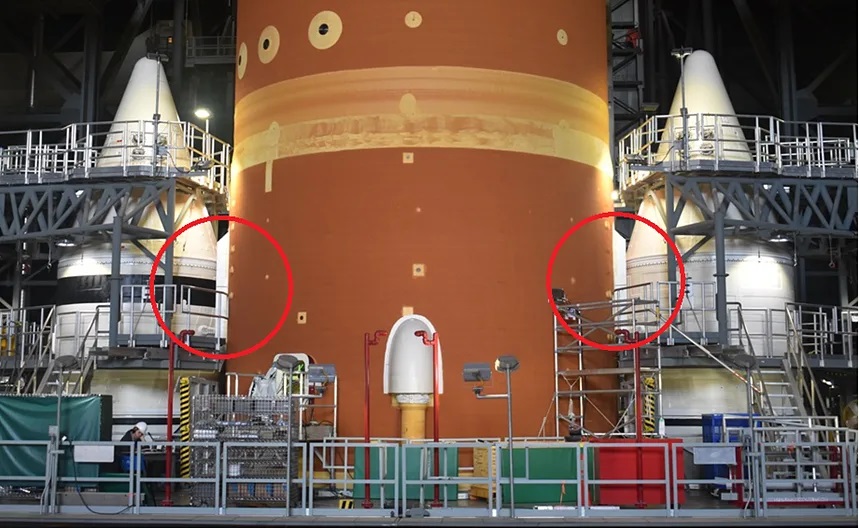

The solution: Together with NASA, Boeing’s SLS team used that challenge to mature their analysis and modeling capabilities. After fine‑tuning wind tunnel testing and computational fluid dynamics simulations, the team quickly identified a simple, effective fix: four strakes — thin, fin-like metal structures — added to the core stage to tame the unsteady flow and reduce vibration for Artemis II and future missions. Strakes are common in aircraft design but new to the SLS core stage.

Red circles identify the strakes in place on the SLS core stage. (© Boeing)

Why it matters: Artemis II will carry humans around the moon. This long-term fix keeps crews safer and will help ensure the stability of future, bigger rockets.

How they did it: The team analyzed wind tunnel data andcomputational fluid dynamics simulations to size and place the metal strakes for optimal performance. By maturing their analysis tools and streamlining decisions with NASA, Boeing engineers were able to translate modeling improvements into hardware quickly — inserting the change in time for the next flight.

- “We immediately pulled together a team—the best of the best,” said Brandon Burroughs, Strake Implementation Team Lead. “The team worked around the clock and even through the year-end break. By working closely with NASA and streamlining processes, we did in weeks what would normally be done in years.”

- Teams practiced drilling holes in Huntsville, Alabama to prepare them for the drilling operation at NASA’s Kennedy Space Center. The team and the strakes were ready to be installed before the core stage was fully stacked on the mobile launcher – avoiding access issues caused by the nearby boosters.

The big picture: Artemis II will be the first crewed flight of SLS and Orion, a roughly 10-day mission around the moon. This work supports NASA’s goal to explore the moon and prepare for crewed Mars missions.