The history of aerospace has shown us the importance of long-term investments in the systems, processes and technologies that make our industry the safest form of transportation.

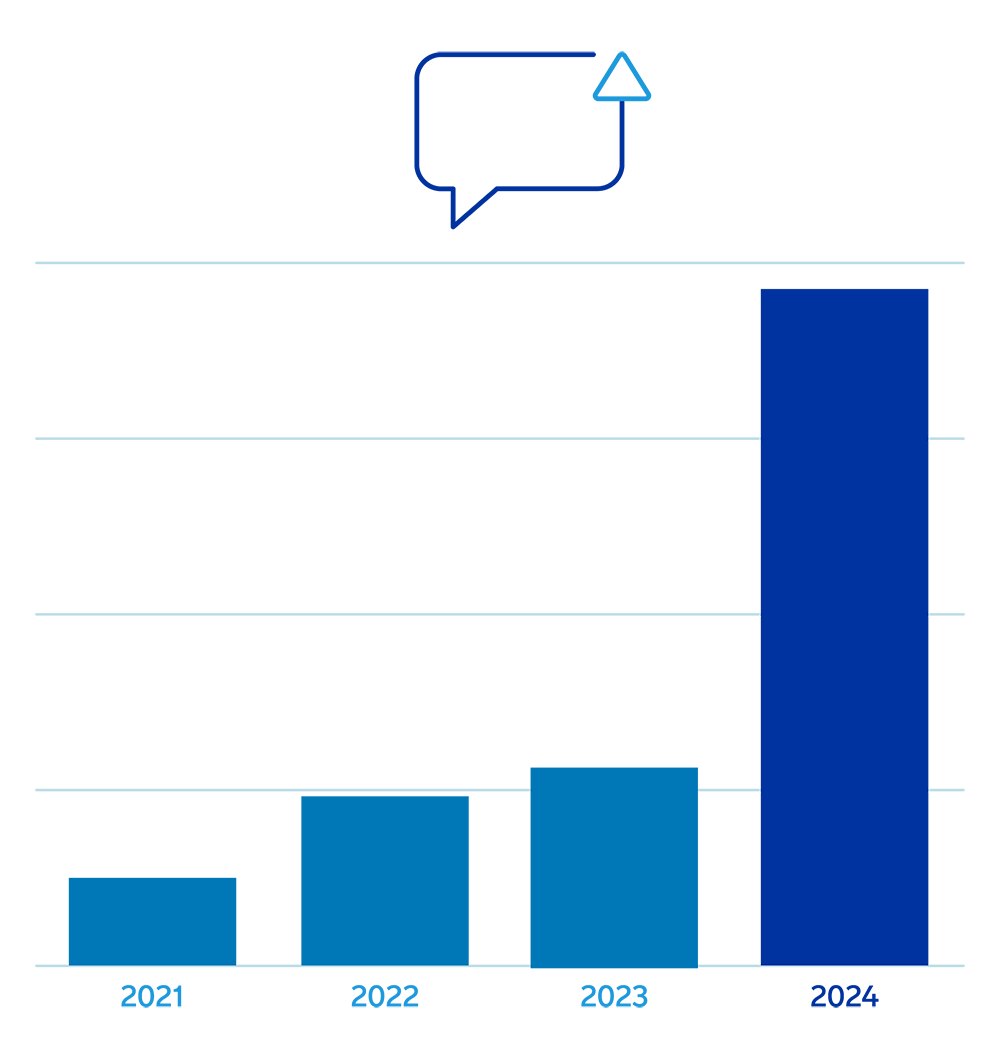

Boeing in recent years has increased its strategic investments in capabilities to drive improvements in the safety of our products and services, and to contribute to the industry’s shared goal of safety.

As Boeing’s second Chief Aerospace Safety Officer, I am privileged to lead teams that are strengthening the safety of our products and services, and I’m proud to share progress on long-term initiatives we started when this independent office was founded in 2021.

It is well understood in our industry that continuous learning is required to achieve the highest levels of safety. The multiple ways we at Boeing are learning – and applying that knowledge – continues to expand. Our learning informs how we design and build our products, how we gather and assess operational data, and how we flow safety improvements back into our engineering processes and out to those who operate and maintain our products.

Our team is the steward and integrator of the enterprise Safety Management System (SMS), which plays a significant and growing role in our company.

Over the past several years we have been working to grow our enterprise SMS. Our perspective broadened after a serious accident in early 2024 involving a mid-exit door plug on a 737-9 that separated from the airplane during flight. We sought guidance – from our regulator, from our customers, from a panel of industry experts, from our own employees. We learned ways to accelerate the alignment, integration and adoption of the enterprise SMS deeper into our three business units and, importantly, far beyond our engineering function into our design, production and product support, as well as our supply chain.

The SMS became a key integrating capability in each business unit’s safety and quality plan. At the same time, our teams continued to make progress on global safety collaborations, data analytics, data sharing initiatives, customer training and support programs, and other long-term investments that help raise the bar ever higher on safety. This gives me confidence that we are on the right path on our safety journey.

This annual report summarizes our progress.

Don Ruhmann

Boeing Chief Aerospace Safety Officer

.png)